Traditional 3D printing methods can sometimes impose limitations on the form, function, and flexibility of the final product. This is primarily due to the inherent nature of the process, where a pliable plastic gel is deposited through the printer nozzle layer by layer. The rapid solidification of each layer affects its overall properties and performance.

World’s First: 3D-Printed Robotic Hand Boasts ‘Bones,’ ‘Ligaments,’ and ‘Tendons’

Now, researchers at ETH Zurich and a US-based start-up have developed a groundbreaking technology that enables seamless 3D printing using different polymers with inherent elastic properties in one go. This advancement heralds a paradigm shift, unlocking novel opportunities for the manufacturing of pliable robotic structures.

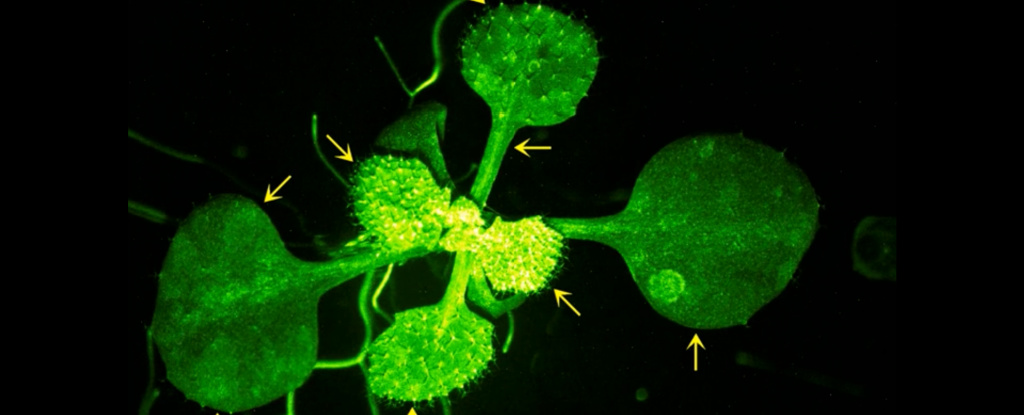

Using this new technology with a groundbreaking combination of 3D printing, laser scanning, and feedback mechanisms, researchers have created the first robotic hand with bones, ligaments, and tendons. It represents a significant advancement in the field of soft robotics, diverging from the conventional use of materials like metal in robot construction.

“Robots made of soft materials, such as the hand we developed, have advantages over conventional robots made of metal,” said Professor Katzschmann, a professor of robotics at ETH Zurich.

“Because they’re soft, there is less risk of injury when they work with humans, and they are better suited to handling fragile goods.”