Researchers from Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have developed a biocompatible material that returns to its original shape no matter what stimuli you applied to it.

Scientists developed this material using keratin leftover Agora wool used in textile manufacturing. Keratin is a fibrous protein found in hair, nails, and shells. This material can be 3D-printed into any shape and can also be “pre-programmed with reversible shape memory.”

Wide range of applications from aerospace to fashion

This biocompatible material can revolutionize the fashion industry. Researchers are hopeful that it could help reduce waste in the fashion industry. As the fabric could stretch to fit the wearer, it can be used for one-size-fits-all clothing.

Kit Parker, the senior author of the paper, said, “With this project, we have shown that not only can we recycle wool but we can build things out of the recycled wool that have never been imagined before,”

“The implications for the sustainability of natural resources are clear. With recycled keratin protein, we can do just as much, or more, than what has been done by shearing animals to date and, in doing so, reduce the environmental impact of the textile and fashion industry.”

Concept Behind:

This amazing material’s shape-changing abilities are because of keratin’s hierarchical structure. Keratin has spring-like structures known as alpha-helix. These structures twist together to form a structure known as a coiled-coil.

Once the fiber is stretched or exposed to a particular stimulus, the coiled-coils uncoil. This allows the fiber to stay in its new position. It will retain its new form until it is triggered to turn back into its original form.

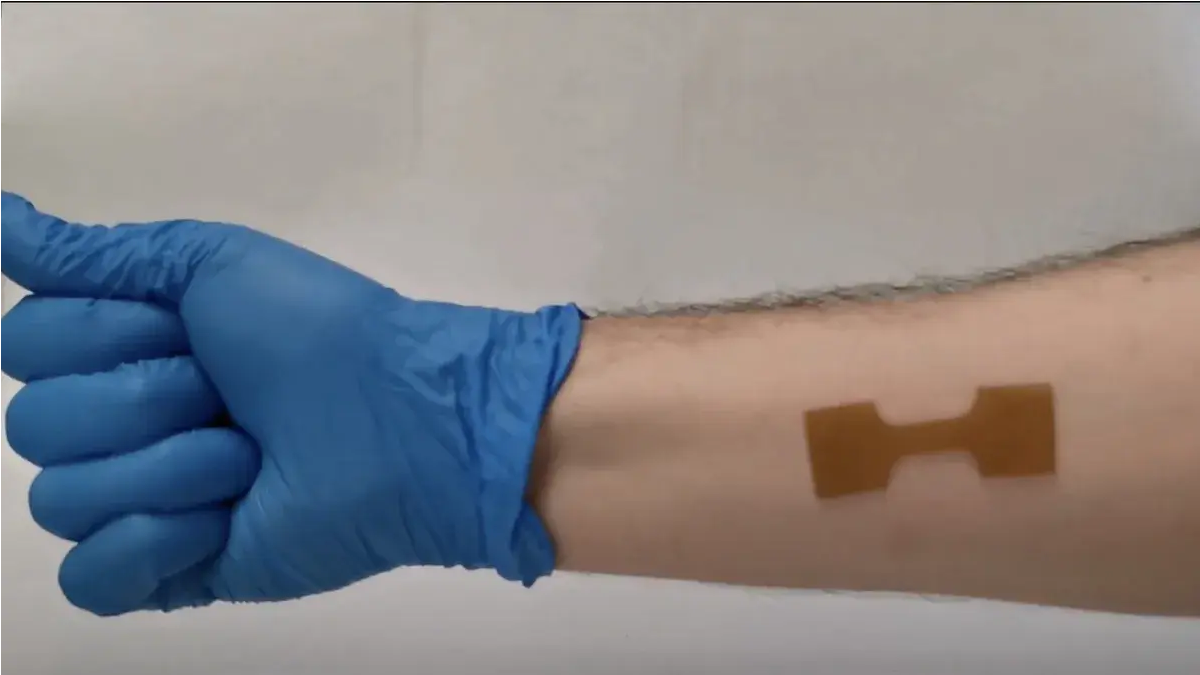

Luca Cera, the first author of the paper, said, “This two-step process of 3-D printing the material and then setting its permanent shapes allows for the fabrication of really complex shapes with structural features down to the micron level. This makes the material suitable for a vast range of applications from textile to tissue engineering.”

Parker said, “Whether you are using fibers like this to make brassieres whose cup size and shape can be customized every day, or you are trying to make actuating textiles for medical therapeutics, the possibilities of Luca’s work are broad and exciting. We are continuing to reimagine textiles by using biological molecules as engineering substrates like they have never been used before.”