Two-thirds of fires on board vessels happen in the engine room and can quickly turn into a disaster for the environment, the people on board and the cargo. These common problems happen when fuel under pressure meets hot surfaces, and an oil leakage detector might be your new life-saving investment. This article will provide you with information regarding oil leakage detectors and the best solutions when an investment is to be made.

How does an oil leakage detector work?

Oil mist is generated from processes that use fuel oils – such as vessels. It reduces the flash point of the oil, allowing it to catch fire in the presence of a hot spot. The oil leakage detector is installed in the engine room and passively monitors the concentration of oil mist and hydrocarbon gases. It acts as a safety alarm that detects if the concentration of mist and or gases rises beyond a set point. If the concentration rises, an alarm will ring and alert the crew on board

A vessel’s engine should be stopped or the speed should be lowered if the oil mist in the engine room is detected past a certain point of igniting.

Why an oil leakage detector is important to install in the engine room

An oil leakage detector does not reduce the amount of oil mist in the engine room but gives a warning if the concentration rises beyond a certain level. These can be major or minor increases, and their detection is reliable and quick. A fire on board is the last thing you would want out on the open sea, and an oil leakage detector is extremely easy to install and does not require much maintenance.

Find the right supplier

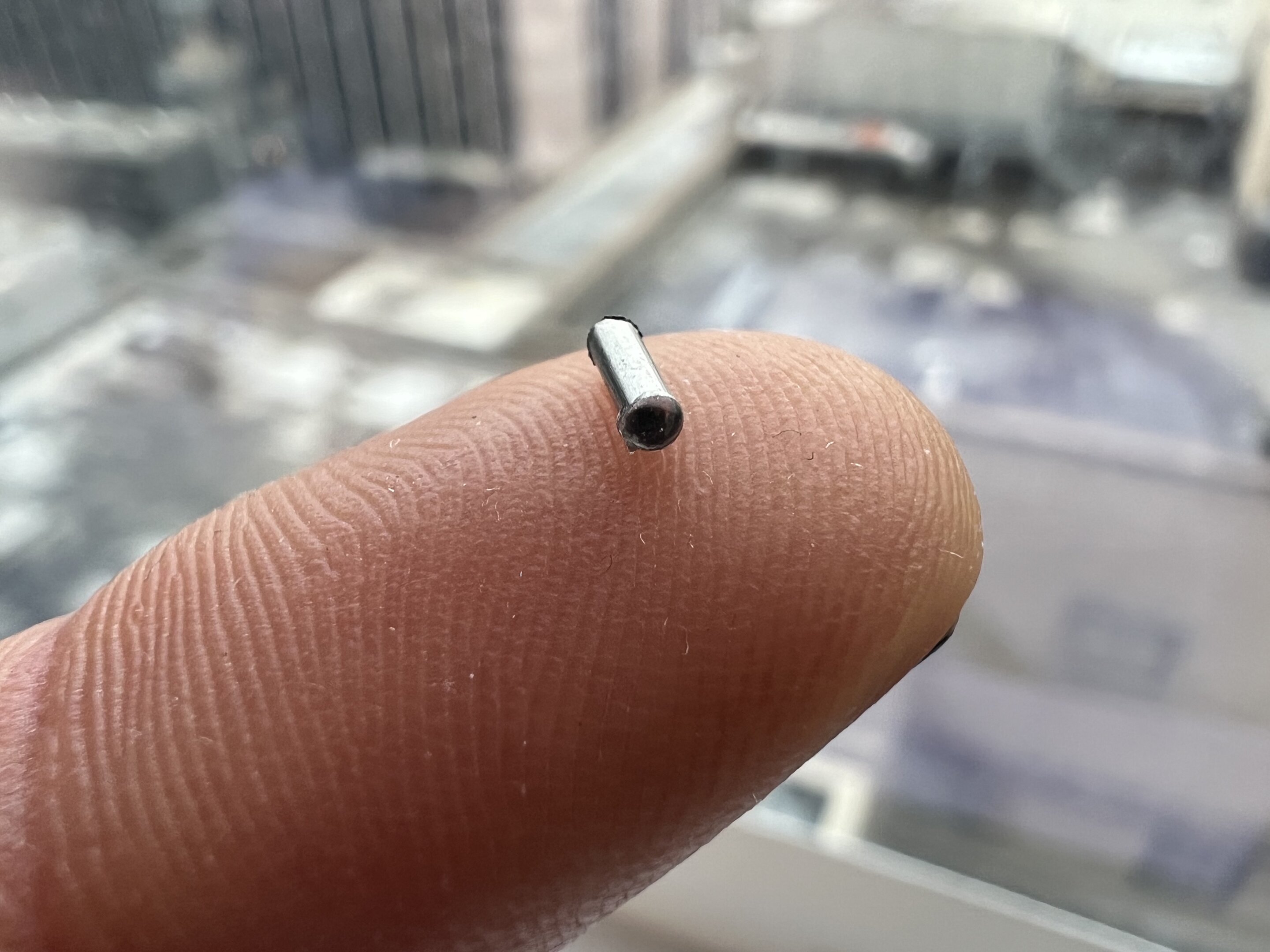

An oil mist detector is an important investment to make. However, there are multiple solutions for securing safety on board vessels. At Daspos, they provide an oil leakage detector like no other on the market. In contrast to traditional oil leakage detectors, Daspos has developed a product that detects problems before they ignite, improving workplace safety.