There’s no way around it: manufacturing is dusty. Whether it’s zinc dust from metalworking, sawdust in carpentry, or even cement dust in construction manufacturing, there are many unpleasant byproducts that come from the creation of the world’s most essential goods. This is why manufacturing facilities must install dust collection systems to handle these contaminants before they become a serious health or safety hazard.

Dust collection systems are a critical component of any facility’s infrastructure, and they must be carefully designed to ensure that they can meet industry standards and match the facility’s output level. Should they not be able to handle the influx of dust, there can be serious concerns for the safety and well-being of everyone who steps into the building, including these most concerning problems that could arise from inadequate dust collection.

Health Risks

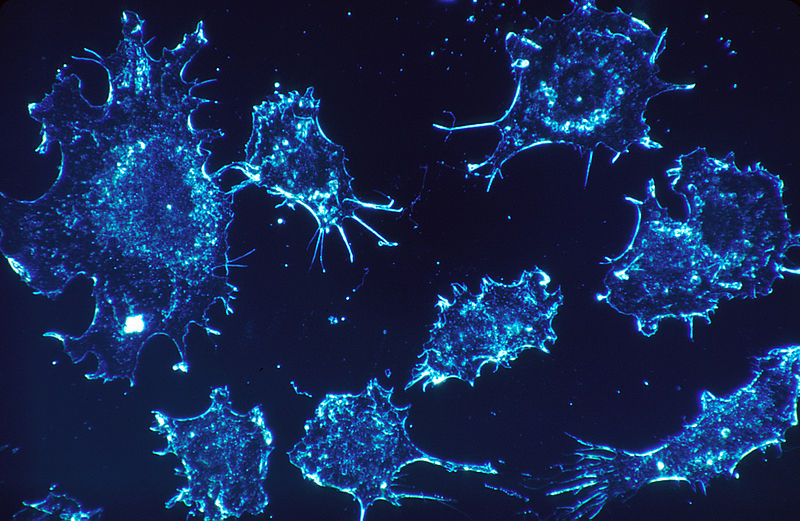

Fine particulates can cause a variety of health concerns for workers, but they often arise from dust inhalation, which leads to respiratory issues. While thankfully, most workers no longer have to fear mesothelioma caused by asbestos manufacture, silicosis is still a major hazard in mining and construction. This incurable disease is caused by breathing in tiny granules of silica, which is found in quartz and other rocks.

Cement dust can also cause pulmonary and respiratory problems, as can the byproducts of woodworking and metalworking. To protect your workers’ lung health, you must be able to suck away and filter these fine particulates, many of which are too small to see.

Fires and Explosions

Dust, such as that from wood shavings and grain, is highly flammable: it only takes a single spark on a pile of wood dust to set a whole factory ablaze. Inadequate dust collection systems will allow these combustible materials to pile up; when the system overheats, it can easily cause a fire within the dust traps themselves, which will eventually spread. Numerous factories have experienced fires due to malfunctioning dust collection infrastructure, and if you don’t work to improve your ventilation and filtering capacities, yours could be next.

Equipment Damage

Manufacturing equipment like conveyor belts is incredibly expensive, so you must do everything possible to protect them from harm. Unfortunately, tiny particles of dust or detritus can foul up moving parts in machinery, leading to premature failure. As the machines must work harder to complete their tasks, they will also begin to heat up, which can cause motor wear and tear. This will lead to line closures and potential loss of revenue, as you won’t be able to meet your output goals for the quarter.

If your equipment is constantly malfunctioning, you should first rule out any defects in the machinery before carefully cleaning it. Should you find a great deal of dust in the parts, this tells you that you need a better dust collection system that will prevent accumulation and allow for smooth operation.

Product Defects

Another concern can be even more hazardous to your bottom line: product issues. It’s especially concerning if this occurs in food or medical manufacturing, where consumer health is on the line, but it can also be a serious issue in other fields like metalworking or construction manufacturing. Faulty products can sicken users or cause catastrophic product failures, such as a car part breaking and potentially leading to a major accident.

If you’re working in the airplane manufacturing or repair industry, small amounts of dust could lead to weak joins between components. This might not be a serious problem at ground level, but at 10,000 feet in the air, the immense pressure and high speeds force air between elements, and something essential like landing gear could easily shear off. You must ensure that every piece is securely sealed, which means that you need to keep the workspace as clean and dust-free as possible.

Of course, it goes without saying that if your product fails and injures someone, you could face fines, lawsuits, and even a permanent closure of your business.

Conclusion

It may be surprising to you exactly how much havoc that near-invisible dust motes can actually cause in your facility, but very serious issues can arise from inadequate dust collection systems. It’s important that you work with a quality installer who can carefully design a system that matches your factory’s needs, as this will ensure that you can run a healthy and safe business. Don’t discount dust as a major disruptor in your facility: it’s much more dangerous than you think. Pay close attention to your dust collector and, when in doubt, consult with a professional who can identify issues and rectify them before they become a major hazard.