Although glass printing is a complicated process, it has remained an interesting sub-field of 3D printing. Researchers have not shied away from the complicated challenge that glass printing presents. Nevertheless, it is a heady process and requires a lot of heat and a lot of luck. A designer has to accept the general belief that the finished glass structure will resemble the design on the screen as well. But one of the things that presents a significant challenge to researchers is the fact that glass cools unevenly.

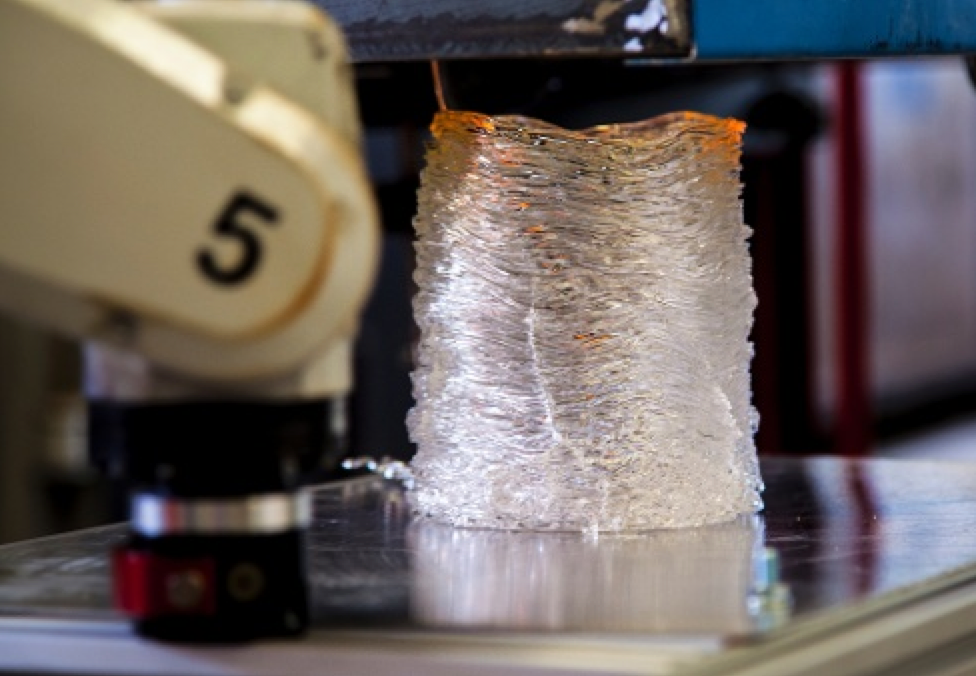

Research teams at Virginia Tech and the Rhode Island School of Design have now created a lab and system for glass printing built atop considerable research. This consistent system of glass design and printing consists of an extruder that produces molten glass, in a form of a narrow squirt, and forms a ceramic tile with the help of a little robotic arm. The robot moves its arm in repetitive motions to create a shape consisting of hundreds of layers of glass. The finished objects are not very complex or high-resolution, but the resulting melting process takes on a primitive and artistic vibe. However, 3D glass printing is a complicated process and to achieve a raw shape of glass structures through it is a considerable achievement.

Stephanie Pander, a glass artist at RISD, said, “This research is an example of innovation that can occur at the intersection of art, design, technology, and science. Instead of a technology-driven approach, we can approach digital fabrication from a place of profound material understanding. This research is evidence that the traditional technical arts will not be replaced by digital fabrication, instead, the technical arts will help to drive and support the direction of future making.”

This is not the first time that researchers have tried to revitalize the ancient mechanism of molding glass through modern technological advancement. The research team at MIT’s Mediated Matter Group introduced a new way to 3D print glass by removing the need to integrate a solid core in a glass structure. The mechanism works by coiling the molten strands that are poured on top of one another like honey. The MIT team of researchers consisted of Neri Oxman and Peter Houk, who were the pioneers of 3D printed glass that looked like optically transparent glass.

The melding of technology and art into a cohesive science has opened several doors for future collaborations in the fields of construction, art, and technology. By 3D printing glass, researchers and designers have proven that 3D printing can be applied through a robotic mechanism to create complex and hard substances, not just plastic and fiber. Only time will tell, though, if the consumer market for the robotic 3D printing mechanism gains the same level of popularity that plastic 3D printing was able to achieve. But the possibilities of utilizing the research for printing glass structures and artistic sculptures are endless and look quite promising.