Researchers have developed a way to create micro LEDs that can be folded, twisted, cut, and stuck to different surfaces.

Researchers foresee these versatile micro LEDs would pave the way for the next generation of flexible, wearable technology.

The concept behind the development

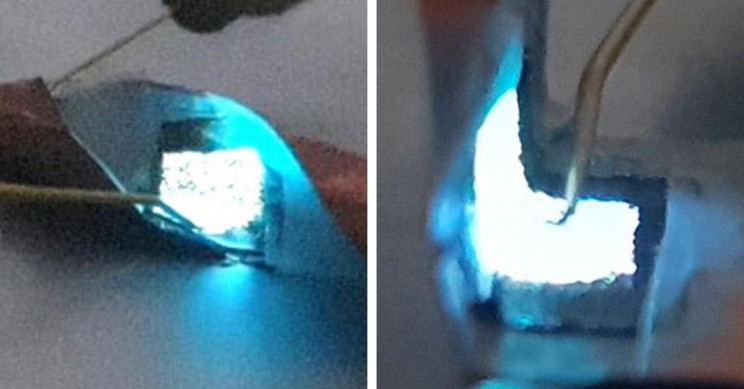

Researchers developed a flexible LED using a technique called remote epitaxy. For releasing the microLED array, the researchers used a non-stick layer of graphene on a sapphire substrate. They constructed the array by using the epitaxy to build vertical microrods of gallium nitride (GaN). After that the array is shifted to a flexible copper sheet.

Dr. Moon Kim, professor at UT Dallas and a corresponding author of the study, said, “The graphene does not form chemical bonds with the LED material, so it adds a layer that allows us to peel the LEDs from the wafer and stick them to any surface,”

Some exceptional benefits of these microLEDs:

- These detachable LEDs can be attached to almost anything.

- If you bend or cut these LEDs, there is no impact on their quality or electronic properties.

- Kim said, “You can transfer it onto your clothing or even rubber that was the main idea. It can survive even if you wrinkle it. If you cut it, you can use half of the LED.”

- These versatile LEDs can be used for flexible lighting, clothing, and wearable biomedical devices.

- Because the microLED array can be detached without breaking the underlying wafer substrate, so the wafer can be used repeatedly.

- Kim said, “It’s very exciting; this method is not limited to one type of material. It’s open to all kinds of materials.”