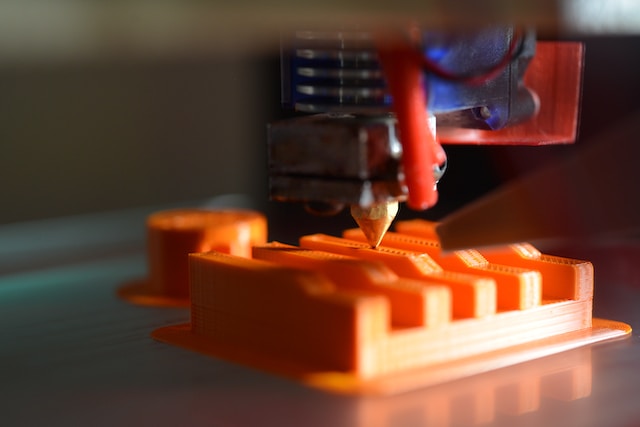

A team of scientists from Jiangnan University, China, developed a technique that makes 3D ceramic printing without the need for support structures possible. This is enabled by the newly developed paste, which is a photosensitive ceramic slurry, meaning that it turns into a solid state and can strengthen immediately after exiting the printing nozzle, due to the near-infrared (NIR) light exposure. Moreover, it is also proven that the effect of NIR is better in comparison to UV light, and enables rapid high-precision 3D printing. The technique was already used for manufacturing structures such as torsion springs and cantilevers.

Ceramics are widely used in the electronics sector, aerospace, as well as mechanical engineering, as a result of their advantages, such as high-temperature tolerance and wear resistance. This revolutionizing method allows such ceramic parts to be produced in three dimensions and from different angles – a previously impossible feature, which included supporting structures, that prevent a collapse of overhanging parts. However, not only did these structures reduce the efficiency of ceramics printing, but a significant problem was also their removal process, which posed a risk to sensitive 3D-printed objects.

With this new increasing efficiency technique, multiscale filaments of diameters (thickness) ranging from 0.41-3.5 mm can be rapidly solidified. As said by Professor Liu Ren for the Nature Communications journal, “The printed curves can be freely extended in space without support. The printing process is smooth and continuous, without the need for heating or cooling,”. In the paper, it is also discussed that “The key to this technology is not only the elimination of the support required in a typical printing process but also brings about many other advantages, such as reduced printing time, material usage and post-processing workload,”. Another benefit of this development is the ability to print mixed ceramics by utilizing iron red, chromium green, or yttria-stabilized zirconia. Furthermore, this method of unsupported 3D ceramic printing will allow complex shape ceramics to be manufactured in the future.