University of California, Los Angeles (UCLA) researchers have developed a material that could one day be used for artificial muscles. The newly developed material is stronger and up to 10 times more flexible than naturally occurring muscles.

The study aimed to replicate the muscles in the body having features similar to biological counterparts’ strength and flexibility. Moreover, the soft material required for artificial muscle should not also lose its form and strength after repeated work cycles.

Qibing Pei, a professor at the University of California Los Angeles (UCLA), and the corresponding author of the study said, “Creating an artificial muscle to enable work and detect force and touch has been one of the grand challenges of science and engineering,”

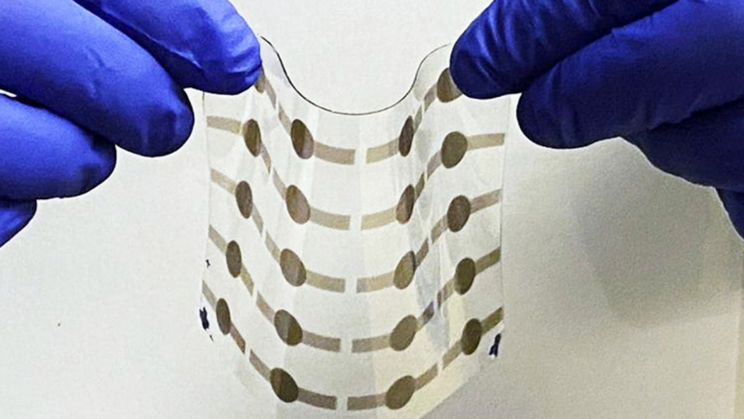

Researchers considered many materials for this, but they put special interest in dielectric elastomers (DE). They considered dielectric elastomers (DE) because of their optimal flexibility and toughness. Dielectric elastomers are light in weight and have high elastic energy density.

Not only this, these can also be made from natural or synthetic compounds and can change size or shape on the application of an electric field. All these properties make them perfect materials to make actuators (machines that can convert electrical energy to mechanical work).

Qibing Pei said, “This flexible, versatile and efficient actuator could open the gates for artificial muscles in new generations of robots, or in sensors and wearable tech that can more accurately mimic or even improve human like motion and capabilities,”

The research has been published in the journal Science.