Supporting U.S. Middle Class in the 21st Century

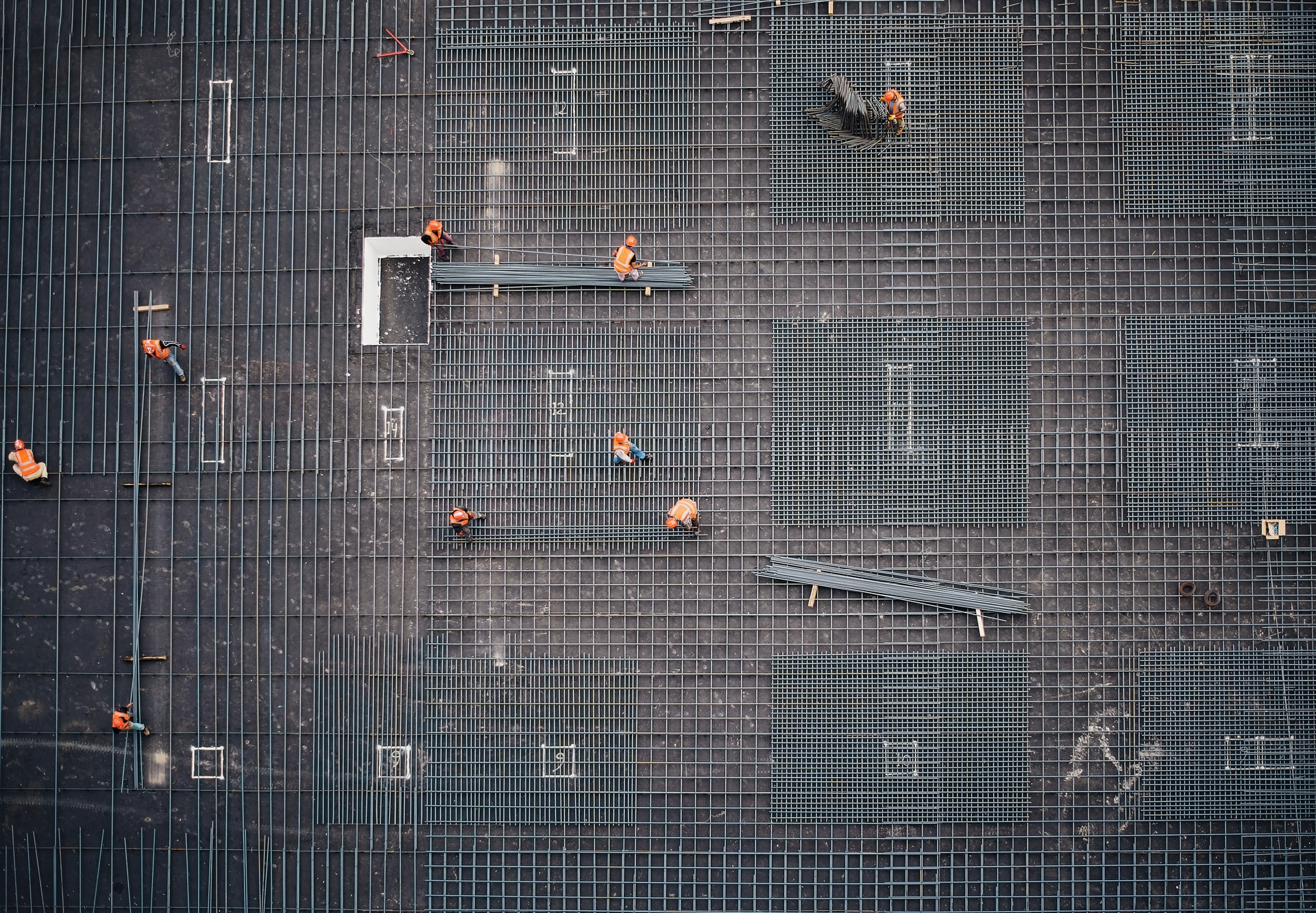

As the U.S. economy slowly improves, American manufacturing is rebounding and companies find themselves cautiously optimistic: output and exports are increasing, new plants are being built, and better paying jobs that require highly-skilled workers are helping the economy climb. However, on “Main Street,” middle-class Americans seem mired in stagnation that many think is the “new normal.”

The media has reported extensively on the new “level” playing field in energy in which the U.S. finds itself a net exporter of energy. But according to a recent report by Helmut Ludwig and Eric Spiegel of Siemens, titled “America’s Real Manufacturing Advantage”, innovation, especially in software, is transforming the American manufacturing sector and putting the country on the path to a sustainable and prolonged expansion for decades to come.

The Changing Manufacturing Paradigm

With new technologies, the decades-old trade-off between efficiency and customization is ending.

The pace of change in global manufacturing is faster than ever before, and factory automation requiring skilled systems integrators who create automated assemblies that improve efficiency and increase productivity are in high demand. The tools of factory automation include programmable logic controllers (PLCs), computers, motion control and drive systems, robots and other leading-edge technology that streamlines manufacturing control and information gathering.

According to the report, the most important element of these new production systems is software that will help in all aspects of manufacturing from addressing customer needs, R&D, and product development, to testing, production and servicing. The report also outlines five ways software will impact product development and production:

- Product Design – new ways of visualizing in simulating product design and testing is leading to more optimized products and processes.

- Production Planning – automated technology is now allowing virtual digital design of entire factories, including each piece of equipment, simulation of production processes and calculation of cost, speed, energy use and quality before anything is actually built.

- Modern Engineering – new software now allows engineers to program and coordinate all automated tasks from a single portal allowing for the improvement of workflows and productivity.

- Manufacturing Execution – software now monitors production performance and execution of systems in real time so that short-term control of manufacturing output and long-term optimization can be improved through production unit reconfiguration.

- Mobile Monitoring – Mobile devices connected to networks producing “big data” and analytics increase service improvement opportunities, the ability to predict failures, and analyze problems, all while reducing costs and improving utilization and productivity.

For the full report, please visit: America’s Real Manufacturing Advantage

Related articles on IndustryTap:

- How To Improve Your End-To-End Manufacturing Processes…

- We All Lose When Global Manufacturing Leadership Fails

- The Rise of Virtually Designed Products and 3D Printers in 21st Century Design and Manufacturing

References and related content: