The Dutch company TouchWind BV presented an innovative solution of a single-bladed wind turbine. In comparison to conventional wind turbines, it is expected that this solution could potentially halve the costs and enable exploiting the significant wind energy potential of the oceans.

The developed design from TouchWind features a single-piece rotor and a large floating buoy at the bottom of the turbine that helps the blade stay out of the water at low wind speeds. On the other hand, at high wind speeds, the single blade will generate lift and therefore pull the turbine into an upright position. While conventional turbines have to automatically shut down at high wind speeds of over 25 m/s (56 mph) in order to prevent damage, this design would enable lower downtime, resulting in more energy production and functionality at wind speeds of 70 m/s (157 mph). The expected decrease in costs for floating wind with this solution is 30%.

Moreover, the design allows easy manufacturing, maintenance, and installation and can be manufactured at harbors that can handle a 200-meter (656 ft) blade for achieving a 12 MW turbine capacity. However, there is currently no exact calculation of how low the levelized cost of electricity (LCOE) will be.

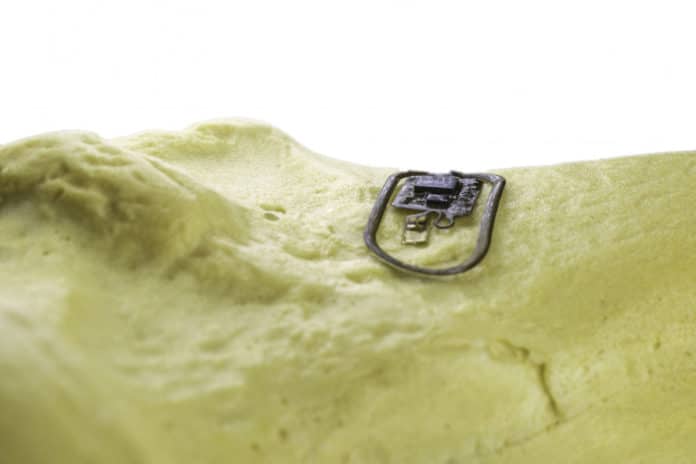

TouchWind has already performed small-scale testing of the turbine and received an investment from the Japanese transport company Mitsui O.S.K. Lines (MOL). As said in a press release by Rikus van de Klippe, TouchWind’s founder and CEO, “We have been working together for a year now on the further development of our floating wind turbine,”, adding that “Field testing with a 6-meter diameter rotor is in full preparation at the Oostvoorne lake in the Netherlands. With MOL as a shareholder and their investments we can speed up our testing program, prove our technology and reduce time to market.”