Scientists from Nanyang Technological University, Singapore have developed a new way of glue activated by magnetic fields. This innovation could lead to serious energy and cost savings for companies that need adhesives on an industrial scale.

Conventional adhesives like epoxy are used to bond plastic, ceramics, and wood. These Conventional glues are typically designed to cure using moisture, heat, or light. Usually, these glues require specific curing temperatures, ranging from room temperature up to 80 degrees Celsius. These glues are quite expensive and energy-consuming.

Now, scientists have developed a method of gluing called “magnetocuring”. This process of gluing does not require anything but a magnetic field.

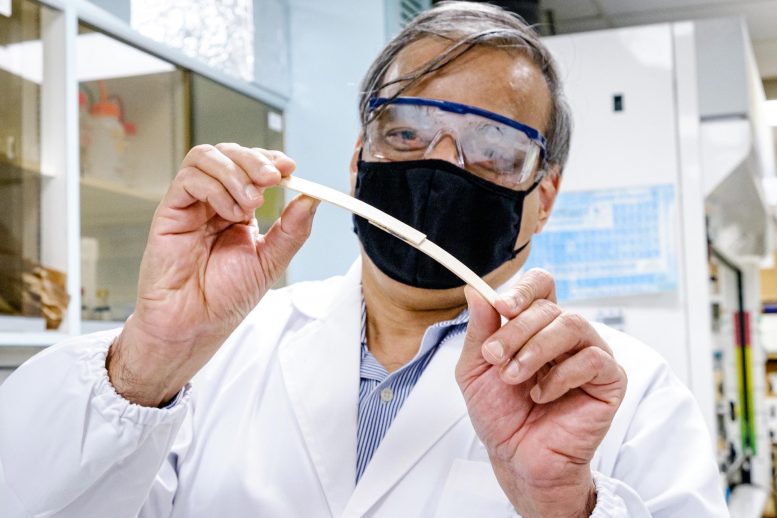

Associate professor Terry Steele, explained, “Our key development is a way to cure adhesives within minutes of exposure to a magnetic field while preventing overheating of the surfaces to which they are applied. This is important as some surfaces that we want to join are extremely heat-sensitive, such as flexible electronics and biodegradable plastics,”

Science behind:

This energy-efficient glue comprises special magnetic nanoparticles. When electromagnetic energy is applied these nanoparticles heat up and bind automatically. This results in a curing process that takes just five minutes. Moreover, it uses less energy than a large conventional oven.

The first author of the study Dr. Richa Chaudhary, “The curing of our newly-developed magnetocuring adhesive takes only several minutes instead of hours, and yet is able to secure surfaces with high strength bonds, which is of considerable interest in the sports, medical, automotive and aerospace industries. This efficient process can also bring about cost savings as the space and energy needed for conventional heat curing are reduced significantly,”