If you delve into the world of electronics manufacturing, you’ll quickly realize that there are numerous factors to consider for a successful manufacturing process.#

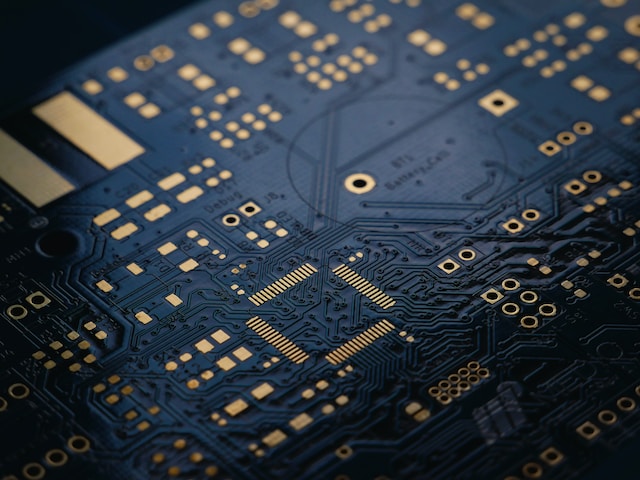

Among these, choosing the right reflow oven is crucial. A reflow oven is an essential piece of equipment that helps solder electronic components onto printed circuit boards (PCBs).

However, with the wide array of options available in the market, finding the perfect reflow oven for your specific needs can be overwhelming.

Importance of a Reflow Oven in Electronics Manufacturing

Before we delve into the details of choosing the right reflow oven, let’s first understand its significance in the electronics manufacturing process.

A reflow oven is responsible for soldering components onto PCBs, ensuring reliable connections and optimal functionality of electronic devices.

It is a critical step in the manufacturing process, affecting both the quality and reliability of the final products.

A reflow oven offers precise temperature control, allowing for the solder to melt and form connections between electronic components, creating solid and secure joints.

It ensures consistent heating across the entire PCB, minimizing the risk of defects such as incomplete soldering or thermal damage.

With the right Trident reflow oven, you can achieve high-quality soldering results, increased productivity, and reduced production costs.

Exploring Different Viewpoints

To make an informed decision on choosing the right reflow oven for your electronics manufacturing process, it’s important to consider different viewpoints. Let’s delve into a few contrasting perspectives and explore their pros and cons.

Cost-Effective Solutions

Some manufacturers prioritize cost-efficiency when selecting a reflow oven.

They opt for budget-friendly options with basic features, focusing on minimizing upfront investment.

These ovens often lack advanced features but can still deliver satisfactory results for simpler electronic assemblies.

However, it’s essential to consider the long-term implications of choosing a cost-effective solution.

While they may save money initially, these ovens might not offer the flexibility, performance, and durability required for complex electronic assemblies.

Investing in a higher-quality reflow oven might result in higher upfront costs, but it can prove to be a wise decision in the long run, ensuring better productivity, reliability, and reduced maintenance costs.

Performance and Precision

On the other side of the spectrum, some manufacturers prioritize performance and precision above all else.

They opt for top-of-the-line reflow ovens with advanced features, such as multiple heating zones, precise temperature control, and real-time monitoring systems.

These ovens offer exceptional soldering results, allowing for the assembly of intricate and high-density PCBs.

While high-performance reflow ovens deliver unparalleled results, they come with a higher price tag.

In addition, their complex controls and sophisticated maintenance requirements might require additional training and expertise.

Manufacturers must carefully evaluate their needs, considering the complexity of their electronic assemblies and the level of precision required, to ensure they make a worthwhile investment.

Customization and Versatility

Another perspective to consider is the need for customization and versatility in the reflow oven.

Some manufacturers require specific features tailored to their unique manufacturing processes.

They may prioritize the ability to program custom temperature profiles, adapt to different board sizes, or accommodate specialized soldering techniques.

Manufacturers with diverse product lines or frequent process changes might benefit from a versatile reflow oven that offers interchangeable parts and flexible settings.

While these ovens may come at a higher price, their adaptability can lead to increased efficiency, reduced setup time, and improved overall performance.

Key Factors to Consider for Choosing the Right Reflow Oven

Now that we’ve examined different viewpoints on choosing a reflow oven, let’s delve into the key factors to consider in your decision-making process.

This will help you select the perfect reflow oven that aligns with your manufacturing requirements.

1. Production Volume and Throughput Requirements

Analyzing your production volume and throughput requirements is crucial in determining the size and capacity of the reflow oven you need.

Consider the number of PCBs you produce per hour, the desired production speed, and any future growth projections.

Choosing an oven that can handle your current and future demands will prevent bottlenecks and ensure uninterrupted operations.

2. Heating Zone Configuration and Control

The heating zone configuration plays a vital role in achieving consistent and reliable results during the soldering process.

Look for a reflow oven that offers multiple heating zones, allowing for different temperature profiles across the PCB.

This feature is particularly important for complex assemblies with components that require specific temperature profiles for proper soldering.

Moreover, precise temperature control is essential for maintaining optimal soldering conditions.

Ensure the reflow oven provides accurate and stable temperature control, minimizing the risk of defects and ensuring high-quality solder joints.

3. PCB Size and Compatibility

Consider the size and compatibility of the reflow oven with your PCBs.

If you produce a variety of PCB sizes, ensure the oven can accommodate the largest and smallest boards.

Some ovens offer adjustable settings or interchangeable tooling to accommodate different board sizes, providing flexibility in your manufacturing process.

4. Conveyor System and Handling Mechanism

A well-designed conveyor system and handling mechanism are essential for smooth and efficient operation within the reflow oven.

Look for features such as adjustable conveyor speed, precise height control, and stable transport to minimize the risk of damage to the PCBs during the soldering process.

A reliable conveyor system ensures consistent results and reduces the need for manual intervention.

5. Maintenance and Support

Consider the availability of maintenance and support services for the reflow oven.

Look for manufacturers with a track record of responsive customer support and readily available spare parts.

Regular maintenance and quick technical support are essential for minimizing downtime, maximizing productivity, and extending the lifespan of the reflow oven.

Tips for Choosing the Right Reflow Oven

Now that we’ve covered the key factors to consider, here are some additional tips to help you choose the right reflow oven:

- Research and compare multiple brands and models: Don’t limit your options. Explore different brands like Trident and compare their offerings to find the best fit for your needs.

- Seek recommendations and reviews: Talk to industry experts, consult with colleagues, or read online reviews to gain insights and recommendations on specific reflow oven models. Real-life experiences and perspectives are invaluable in the decision-making process.

- Evaluate the warranty and after-sales support: Ensure the reflow oven comes with a warranty, and carefully review the terms and conditions. A comprehensive warranty and reliable after-sales support provide peace of mind and protection against unforeseen circumstances.

- Consider energy efficiency: Look for reflow ovens with energy-saving features. This not only reduces operational costs but also aligns with environmental sustainability efforts.

- Visit trade shows and exhibitions: Attending trade shows and exhibitions related to electronics manufacturing can provide hands-on experience with different reflow ovens. You can interact with manufacturers, ask questions, and gain a deeper understanding of the available options.

Personal Perspective and Experience

As someone who has been involved in the electronics manufacturing industry for years, I’ve had my fair share of experiences with reflow ovens.

One particular instance stands out in my memory. We were producing a high-density PCB assembly for a revolutionary medical device.

We initially opted for a budget reflow oven to save on costs. However, we soon realized that the oven couldn’t handle the complex temperature profiles required for the assembly.

After careful evaluation, we decided to invest in a high-performance reflow oven with precise temperature control and advanced features.

The results were remarkable. We achieved flawless soldering joints and increased production efficiency. Our decision to prioritize performance over cost ended up saving us time and money in the long run.

Conclusion

Choosing the right reflow oven is a critical decision for any electronics manufacturer.

By considering different viewpoints, and evaluating key factors such as production volume, heating zone configuration, PCB compatibility, conveyor system, and maintenance support, you can make an informed decision that aligns with your specific manufacturing needs.

Remember, there is no one-size-fits-all solution.

Consider your unique requirements and analyze the pros and cons of different options before making a final decision.

By investing in the right reflow oven, you’ll ensure high-quality soldering, increased productivity, and long-term success in the challenging world of electronics manufacturing.