Manufacturing processes have come a long way since the dawn of the Industrial Revolution. Today, industries rely on a wide range of advanced technologies to produce high-quality products efficiently and consistently. One such technology that plays a crucial but often overlooked role in manufacturing is vacuum technology. Vacuums are used in various stages of manufacturing to improve product quality, increase productivity, and ensure safety. Below are just some of the diverse roles that vacuums play in modern manufacturing processes.

Vacuum Forming

Vacuum forming is a popular manufacturing technique used to create plastic products, packaging materials, and a variety of other items. A plastic sheet is heated until it becomes pliable, and then it is stretched over a mold while a vacuum is applied to remove air from between the plastic and the mold. The vacuum ensures that the plastic conforms precisely to the mold’s shape, resulting in products with consistent dimensions and high-quality surface finishes. This process is widely used in industries such as automotive, aerospace, and consumer goods.

Vacuum Packaging

Vacuum packaging is essential in the food and pharmaceutical industries. It involves removing air from packaging containers, typically plastic bags or containers, before sealing them. This process extends the shelf life of products by preventing the growth of spoilage microorganisms and preserving the freshness of the contents. Vacuum-sealed packages are also more compact and durable, making them ideal for storage and transportation.

Vacuum Metallurgy

Vacuum metallurgy is a specialized manufacturing technique used to produce high-purity metals and alloys. By removing impurities and gases from the production environment, vacuum chambers create a controlled atmosphere that allows for precise control over the metallurgical processes. This results in metals with superior mechanical properties, making them suitable for critical applications in aerospace, electronics, and medical devices.

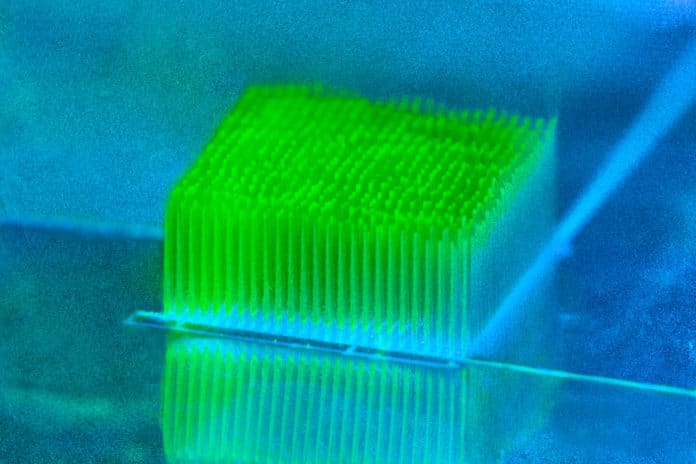

Semiconductor Manufacturing

The semiconductor industry relies heavily on vacuum technology. In the fabrication of microchips and electronic components, vacuum chambers are used in various processes, including chemical vapor deposition (CVD) and physical vapor deposition (PVD). Vacuums create the necessary conditions for depositing thin films of materials onto silicon wafers, enabling the production of highly integrated and miniaturized electronic devices.

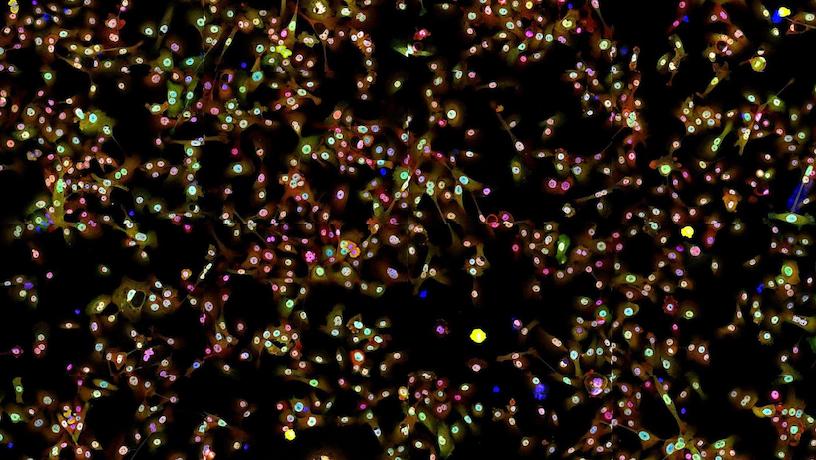

Cleanroom Environments

Many manufacturing processes require a controlled and clean environment to prevent contamination. Different types of vacuum pumps are used to maintain cleanroom conditions by removing dust, particles, and other contaminants from the air. This is crucial in industries like pharmaceuticals, electronics, and biotechnology, where even the tiniest particle can lead to product defects or compromised safety.

Material Handling

Vacuum technology is also employed in material handling processes. Vacuum lifters and manipulators are used to safely move heavy or fragile materials in manufacturing facilities. These devices rely on vacuum suction cups to grip and lift objects, reducing the risk of damage or injury associated with traditional lifting methods.

Leak Testing

Ensuring the integrity of products is vital in many industries, including automotive, aerospace, and medical devices. Vacuums are used for leak testing to identify any defects or weaknesses in sealed components. By subjecting the product to a vacuum and monitoring pressure changes, manufacturers can identify and address potential issues before the product reaches the market.

In conclusion, vacuums play a multifaceted role in modern manufacturing, contributing to product quality, efficiency, and safety across various industries. From vacuum forming to semiconductor manufacturing and cleanroom environments, vacuum technology has become an indispensable part of the manufacturing landscape. As technology continues to advance, vacuums are likely to play an even more significant role in shaping the future of manufacturing.