The manufacturing industry has experienced significant technological advancements lately. This has changed how goods are produced and revolutionized the manufacturing process. These advancements have enhanced manufacturing and opened new business possibilities to expand and grow. The new technologies are aiding manufacturers in reducing human intervention. This has increased plant productivity and give a competitive edge. This article explores the latest technological advances in this industry and how this change can benefit your business.

1. Automation

Automation is one of the manufacturing industry’s crucial and most significant technological advances. Automation has allowed many companies to automate repetitive and also time-consuming tasks. The automation processes have reduced labor expenses and allowed many businesses to enjoy a competitive edge in the global market. Companies can produce goods faster with better accuracy, consistency, and fewer mistakes on platforms like judi slot online.

One of the practical applications of automation processes is using robots in manufacturing. Using robots for manufacturing is an easy way to do tasks that are complex and impossible to be done by humans. Robots are more effective if the work is in hazardous environments or lifting heavy loads. Besides, robots are designed to work 24/7, which leads to increased production within a short time.

2. Virtual Reality (VR)

Virtual reality helps to simplify the product design process. VR eliminates the need to design complex prototypes. VR has taken the manufacturing industry by storm. VR is used to create immersive simulations of the manufacturing process. This allows businesses to test new techniques and equipment before investing in them. It also helps companies to avoid costly mistakes. In addition, you can identify the areas and opportunities to improve on.

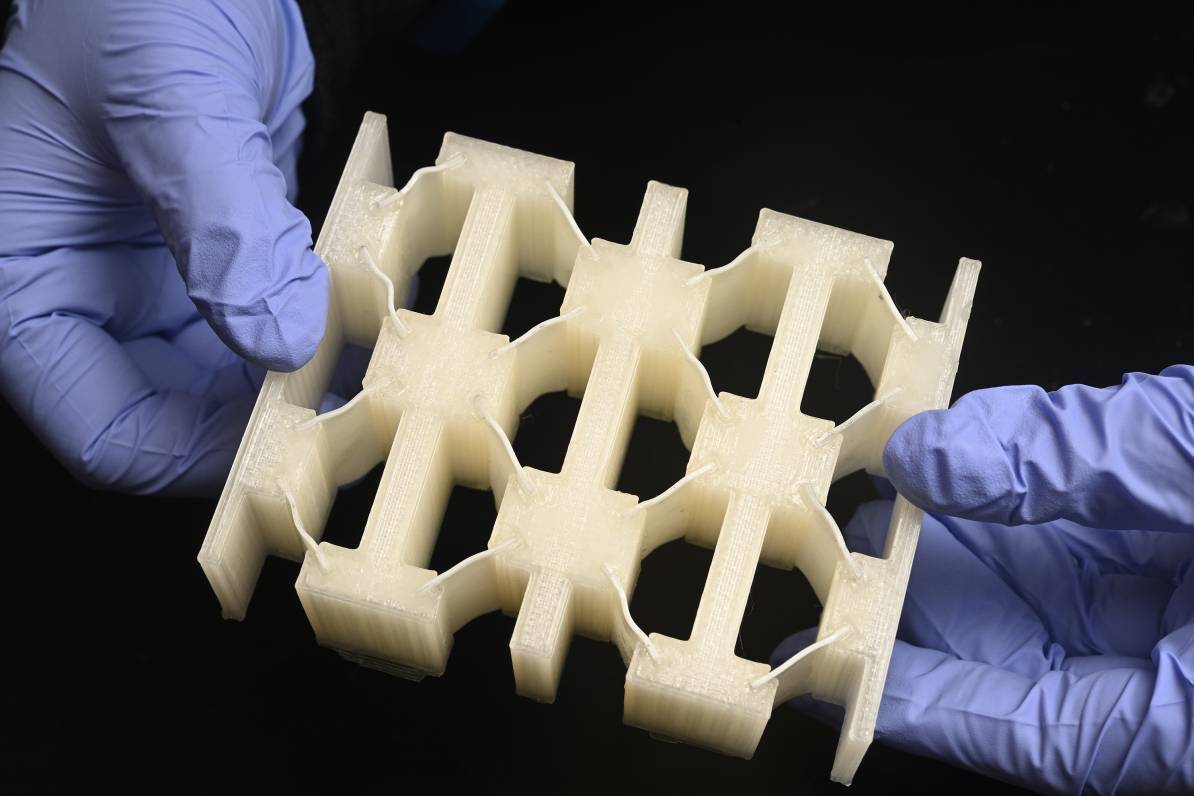

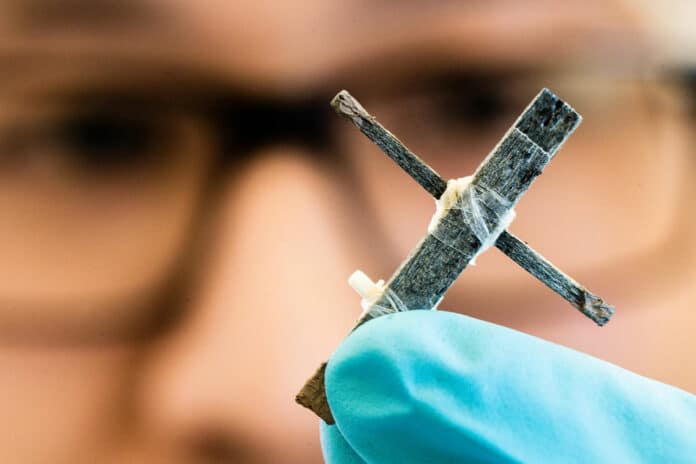

3. 3D-printing

3D printing is a new technology that has been around for a while. However, the latest advancements have made it accessible and more affordable for businesses. Using 3D printing helps to create prototypes and products fast and efficiently. You don’t need expensive tooling to do this. This helps to reduce the lead times and helps for excellent customization of your products.

Another advantage of 3D printing is that it has allowed businesses to produce small batches of products cost-effectively. This is especially useful for companies that manufacture customized products where it might be cost-effective to produce large volumes. Use platforms like slot online terpercaya for the best service.

4. Artificial Intelligence (AI)

AI is another game-changing technology adopted in the manufacturing industry. Artificial intelligence analyzes large amounts of data stored in platforms like judi slot online to examine patterns and insights that can help your business grow and improve the manufacturing process. Companies can easily predict equipment failures before they happen. This helps to optimize production schedules and to reduce wastage. Another use of AI in the manufacturing industry is predictive maintenance. With this application, you can monitor your manufacturing equipment in real-time. This way, you can tell when service is necessary. This way, you can avoid them breaking down unexpectedly. It helps to prevent breakdowns that can lead to downtime and unexpected delays. It allows businesses to save money and time in the manufacturing process. Companies can schedule regular maintenance services.

AI is a perfect plan to avoid downtime moments impacting the manufacturing process. The best platforms slot online terpercaya has crucial tools to help you conduct the analysis.