The manufacturing sector has drastically changed in the last couple of years. Without a doubt, its future is tied to technology. Digital technologies like artificial intelligence, 3D printing, and robotics have become indispensable for manufacturers looking to increase productivity and remain competitive.

This fundamental shift is driven by many factors. The most significant factors include labor dynamics, political realignments, and the push for sustainability. In this article, we dig into some insights and highlight tech trends shaping the sector’s future.

Insights into manufacturing: employment is shrinking

In the post-World War-2 era, manufacturing was a key employer in the US and many advanced economies. However, this is no longer the case. According to the International Labor Organization (ILO), manufacturing dropped from a commanding 26% of total employment in the US in 1991 to about 20% in 2019.

There are two main reasons for this trend:

- Many manufacturers shifted to emerging economies like China

- Manufacturers adopted technologies to improve productivity. Fewer workers were needed to achieve similar outputs.

Even though political waves like the “Make America Great Again,” and “Brexit,” created storms and increased employment, manufacturing employment is still low. Even though manufacturers re-shored their operations, they opted for technologies. Machines were better at mitigating issues like COVID-19, and higher labor costs. Besides, technology offered better solutions to meet sustainability demands, like green manufacturing solutions.

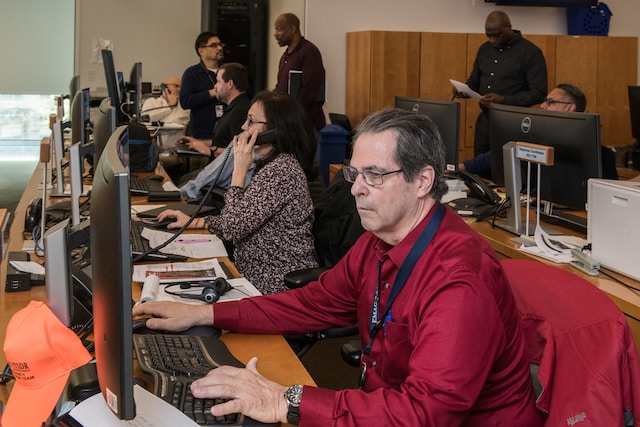

The digital transformation in manufacturing, dubbed industry 4.0, comprised emerging technologies that aimed to improve various aspects of manufacturing operations. Below, we explore four key tech trends in the revolution.

Design software and digital twins

During the development of a product or machine part, it is often necessary to run simulations and ensure that it can withstand the application. This is where design software is needed to perform element analysis. The results from the assessment would give users some degree of confidence in the application performance of the product or equipment.

Excellent design software analyses provide parameters like aerodynamics, heat transfer, and fluid flow. Some software can fit multiple industries, and give more conclusive information like reliability, sensitivity, and robustness. Thus, quicker and better decision-making.

After completing the design phase, manufacturers check the suitability and performance using a digital twin. At its most basic, a digital twin is a virtual model of the physical item. It could be a part of the equipment or a product. But the virtual representation improves the design phase by reducing the number of iterations done on a physical prototype.

Manufacturers that invest in digital twin technologies may improve the cycle times of critical processes by as much as 30%. In addition, digital twin technologies can help streamline processes, predict and mitigate equipment maintenance, lengthen product life, and inspire collaborations.

3D printing

Although digital twin technologies can significantly improve the design aspect and sharpen the process, prototyping is inevitable. It offers immense benefits to manufacturers. However, more manufacturers are turning away from traditional methods of crafting prototypes and adapting 3D printing technology.

The process makes physical prototypes redundant, therefore it enables accelerated prototyping. It also enhances product development and improves the flexibility of the design process because users can get a hold of the actual product before it is manufactured.

Automation & robotics

Once the designs are complete, manufacturers must think of affordable ways to mass produce.

Previously, this was up to humans and a few machines. However, due to high labor costs, demands for better quality, and requirements to improve efficiency, manufacturers turned to automated systems.

Assembly robots and other technologies like collaborative robots (cobots) can significantly reduce production costs and enhance production efficacy. Manufacturers can couple robots with technologies like artificial intelligence (AI), and use them to complete menial tasks. Additionally, innovations like OEE software can be deployed to ensure core systems always run as efficiently as possible, boosting productivity and flexibility at a fraction of historic costs. One manufacturer – Universal Robots – claims that some of their robot arms are easy to set up, and one can recoup its investment in less than 200 days.

Industrial Internet of Things (IIoT)

Closely connected to artificial intelligence is the Industrial Internet of Things IIoT. This is the use of interconnected devices in industrial-level applications. Whereas IIoT could comprise multiple devices and instruments, few applications exist. One of the most common manufacturing applications is connected sensors.

Interlinked sensors offer several benefits from the supply chain, inventory management, and self-optimization. Connected sensors can also collect valuable data giving insights into the production process. The insights can help increase savings, streamline processes, boost sustainability practices, and more.

Conclusion

Manufacturing today is not what it used to be a decade ago. Companies have become more efficient by embracing technologies. As global competition becomes stiffer, only the most efficient players will thrive. Manufacturers must invest in new technologies and continuously improve efficiency to boost productivity. As digitization becomes the sector standard, players who invest in the mentioned technologies are more likely to survive competitive pressure and thrive.