In this day and age, small submarines, ROVs (remotely operated vehicles), UUVs (unmanned underwater vehicles), commonly referred to as underwater drones, and off-shore drilling are all big business.

Now more than ever, we have the technology required to safely and extensively deploy underwater robots for wide-ranging scientific and safety applications.

Perhaps no one component built into these vehicles is more important than the high-tech submersible sensors companies like Positek are continuously developing and improving.

Positek offers two kinds of submersible sensors, linear and tilt, rated from 10 bar to 350 bar.

For some perspective, 10 bar is equivalent to 150psi or 100m depth (about 294 ft), while 350 bar translates to 5000psi or 3500m depth (about 11482 feet).

This means an underwater vehicle equipped with a LIPS® 125 rugged submersible stand-alone linear position sensor sealed to 350 bar can feasibly dive more than 2 miles deep into the ocean.

Impressive, right?!

In the past, these submersible sensors had to be custom made by manufacturers, meaning there was not a lot of standardization, which ultimately resulted in the sensors being tagged with extremely steep prices.

Not only are Positek’s submersible sensors more affordable given their capabilities, but the products are also helping pave the way for groundbreaking research and discoveries with the help of small submarines, ROVs, and UUVs.

Additionally, Positek’s submersible sensors have found extensive use in off-shore drilling applications due to the fact the company offers systems that are intrinsically safe at the surface level.

When underwater vehicles are submerged, they are generally not in an explosive environment.

However, once vehicles rise to the base of an oil rig, they are then considered to be in an explosive environment, which is where Positek is able to minimize risks thanks to their intrinsically safe sensors at the surface.

With how much money, time, and effort are poured into off-shore drilling, you can see why using a trusted submersible sensor is absolutely critical.

Incredibly, Positek has been unable to break these submersible sensors during pressure testing thus far, representing enormous potential for even more promising applications in the future, such as for military and defense purposes.

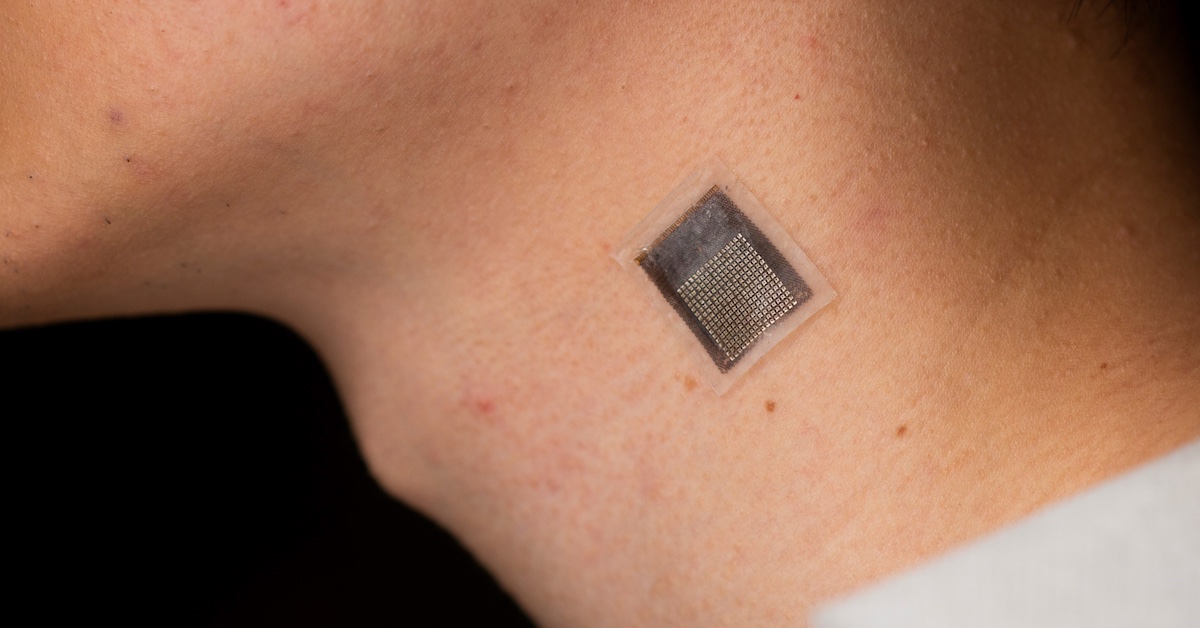

The Positek micro electronic interface which produces the output signal is combined into a single custom ASIC with the minimum of additional surface mount components. The interface, which has a high level of EMC protection built in, needs a DC supply and a range of electrical I/O options are available to suit customer requirements.

Request More Information About Positek’s Submersible Sensors: