Roughly 36% of CO2 emissions can be attributed to manufacturing industries globally. The use of sustainable energy to power industry could theoretically with advancements remove the carbon byproduct, but up until now, sustainable energy has lacked the efficiency to substitute fossil fuels.

But by ‘sandwiching’ tiny layers of metal and plastic, Princeton University researchers have been able to overcome the core challenges facing solar cell efficiency; namely light reflection, and the inability to hold collected light fully. The new technique boasts a reflection rate of just 4% of light!

However the real challenge is indirect sunlight, such as when a cell is mounted on a slanted roof, or when light is obscured by cloud; here the structure achieves 81% additional efficiency, meaning solar cells could be mounted on to a roof and provide ALL the needed energy for its daily consumption, even on days without perfect summer weather.

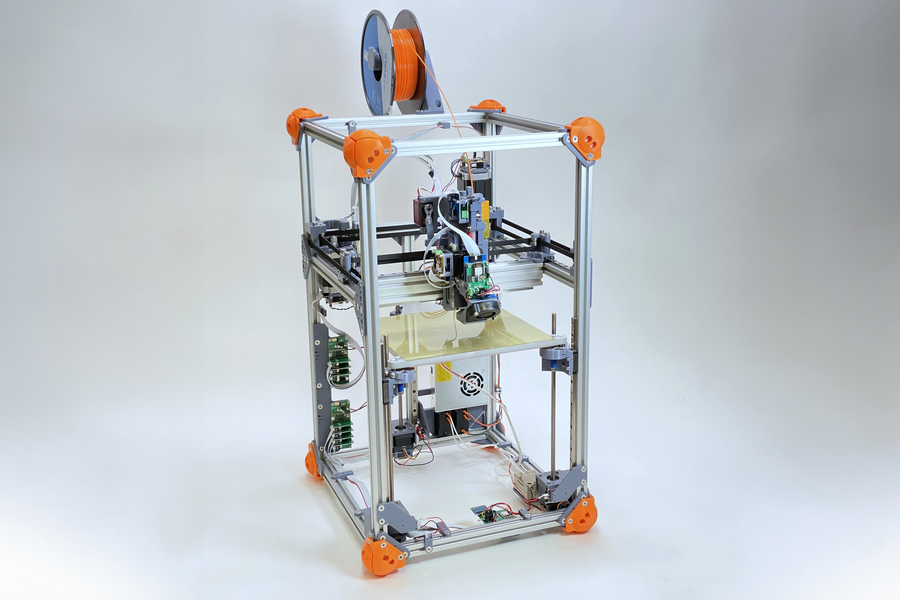

Best of all the new tiny structure of the cells can be embossed over a large area, similar to newspaper printing. This means entire faces of buildings could be covered in solar cells, at triple the efficiency of the current standard available, and a fraction of the cost!

This extreme bendable property means that it can be adapted to any existing building: No remodeling or lengthy and extensive installation process would be needed. A one time fee to make facilities not only pay for the resources it uses, but possibly even generate income by selling power back to the grid!

Efficiency is only set to rise as research continues. In time solar power may become the best economic choice.