For any athletic or fitness activity, proper body biomechanics is necessary. To optimize performance and avoid injuries, athletes use custom-made insoles.

But the problem with hand-made insoles is that optimizations and adjustments take time. Also, the pressure profile of the feet is measured over pressure-sensitive mats, but not during workouts or outdoor activities.

Now an invention by a research team from Switzerland could greatly improve things!

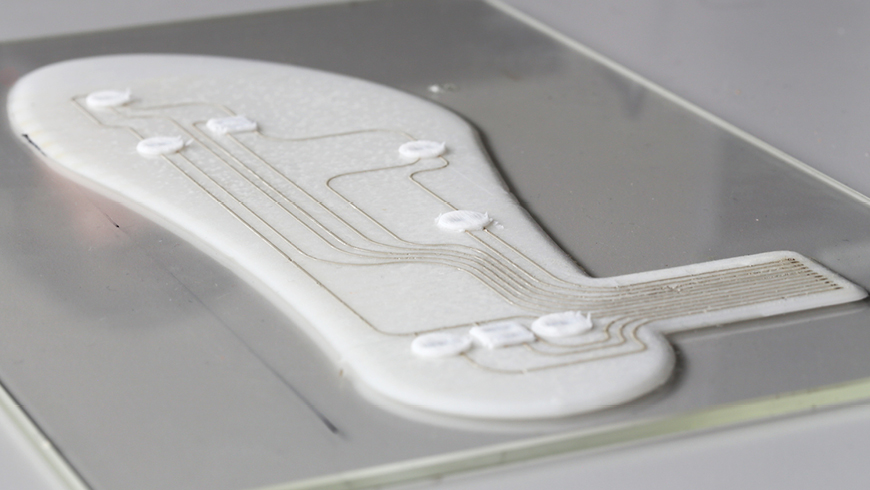

The researchers at ETH Zurich, Empa, and EPFL created a 3D-printed insole with integrated sensors to measure sole pressure directly in the shoe during various activities. The insoles are produced in just one step on a 3D printer, called an extruder.

The 3D-printed insole will make the mat tests a thing of the past!

“You can tell from the pressure patterns detected whether someone is walking, running, climbing stairs, or even carrying a heavy load on their back – in which case the pressure shifts more to the heel,” explains co-project leader Gilberto Siqueira, Senior Assistant at Empa and ETH Complex Materials Laboratory.

“So with data analysis, we can actually identify different activities based on which sensors responded and how strong that response was,” Siqueira added.

In the future, based on such measurement data, permanent shoe insoles with different hard and soft zones can be produced using 3D printing.

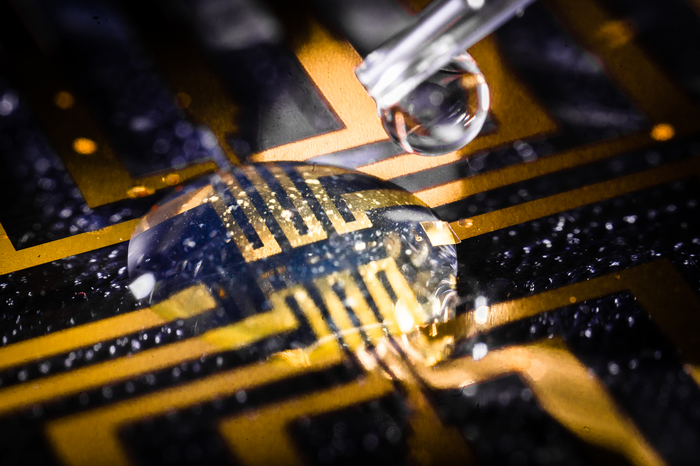

EPFL researchers supplied the sensors, while the ETH researchers developed the inks and the printing platform. The Lausanne University Hospital (CHUV) and the orthopedics company Numo were also involved in the project.

Smart 3D-Printed Insoles Map the Sole Pressure Directly in The Shoe

By: | March 22nd, 2023

Image courtesy: Marco Binelli, ETH Zurich

More articles from Industry Tap...