In metallurgy, it is a known fact that smaller grain size will make the material harder. Using this property, researchers have found a way to develop metals that are times harder than naturally occurring structures.

Science behind:

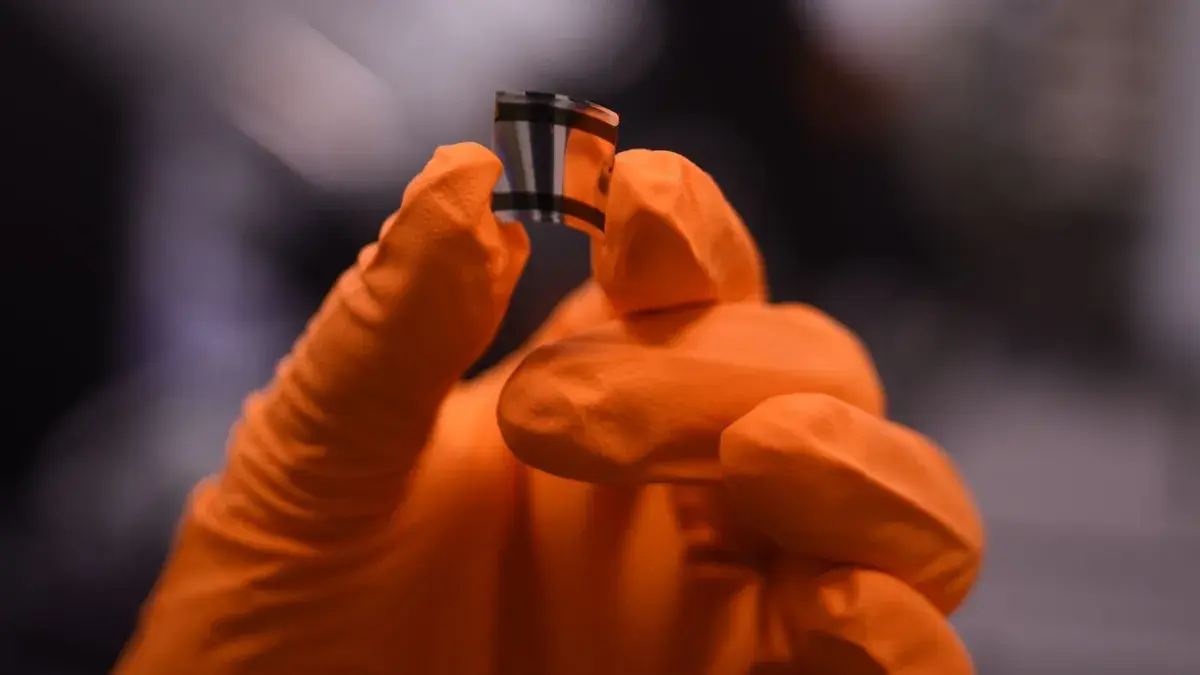

Brown University researchers have discovered a way of smashing individual metal nanoclusters to form harder metals. They created “nanoparticle building blocks” that are squeezed to fuse for creating uniform grain sizes. These harder metals were found to be up to four times harder than naturally occurring metal structures.

Ou Chen, corresponding author of the new research, said, “Hammering and other hardening methods are all top-down ways of altering grain structure, and it’s very hard to control the grain size you end up with,”

“What we’ve done is create nanoparticle building blocks that fuse together when you squeeze them. This way we can have uniform grain sizes that can be precisely tuned for enhanced properties.”

Researchers used nanoparticles of gold, silver, palladium, and other metals for this study. For this, the metal nanoparticles were given the chemical treatment. This treatment chemically stripped them of the organic molecules called ligands. These ligands usually prevent the formation of metal-metal bonds between particles. As the result, the clusters were able to fuse with very little pressure.

So formed metal coins were found to have properties like electrical conduction and light reflectance nearly similar to standard metals. However, their optical properties were found to be dramatically changed.

“Because of what’s known as the plasmonic effect, gold nanoparticles are actually purplish-black in color,” Chen said. “But when we applied pressure, we see these purplish clusters suddenly turn to a bright gold color. That’s one of the ways we knew we had actually formed bulk gold.”

Now researchers are planning to use this technique in commercial products.

Chen added, “We think there’s a lot of potential here, both for industry and for the scientific research community,”