Chances are, if you like the car seat you are sitting on in terms of comfort and durability, you have both robot dummies and humans to thank. Robots can be programmed and shaped to mimic humans of all shapes and sizes to “cycle test” automobile seats and other automobile components for wear and durability. Cycle testing with robots ensures that products leaving the manufacturing line will have a good chance of functioning as designed.

Cycle testing allows manufacturers to have a good idea of how a seat will look and how its cushions and seat structure will be affected over a lifetime of use. Robot dummies can be designed and programmed to exactly mimic the compressive force placed on seats by humans who are bony, wide, heavy, etc.

In addition to testing durability of seats, robots can be used to verify whether installed components such as car seat heaters integrated into a seat can withstand the mechanical stress they are subjected to over their lifetimes.

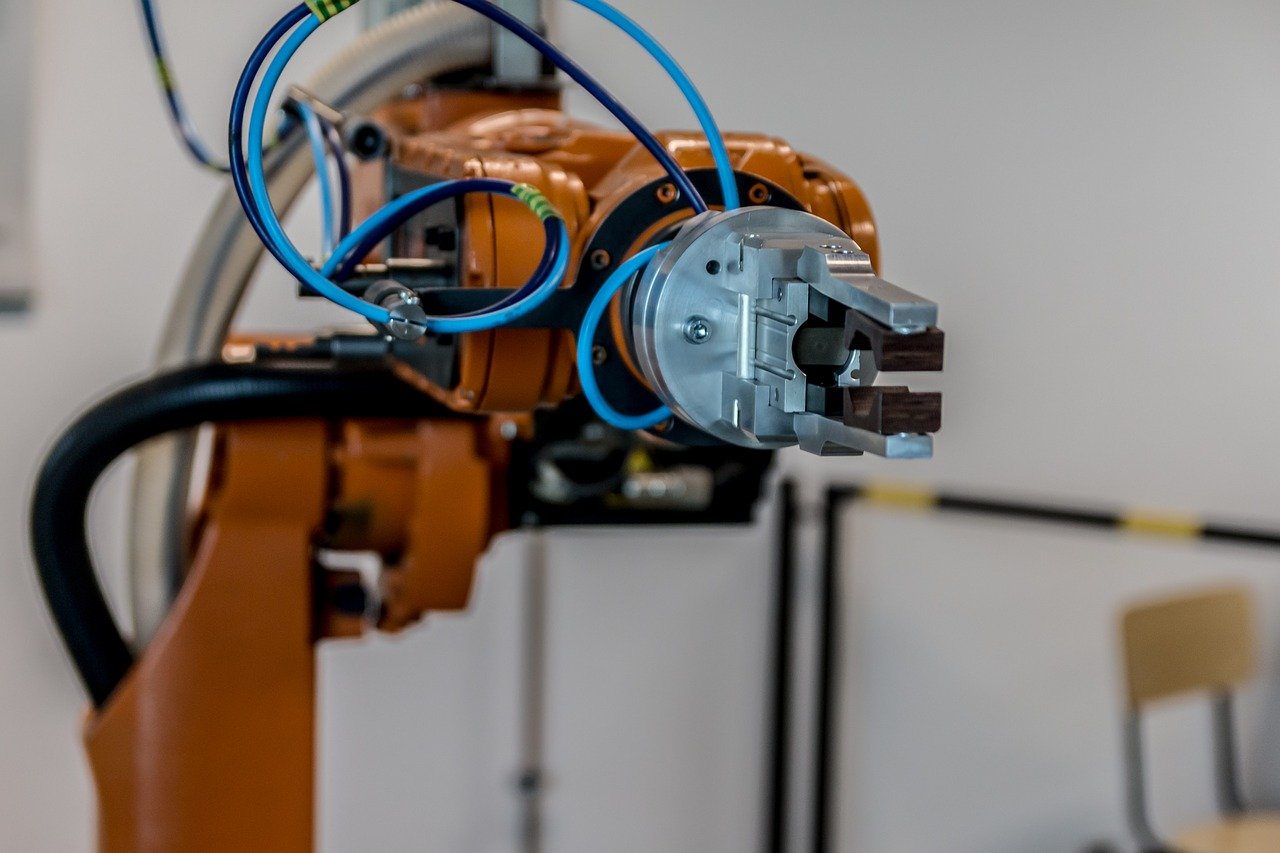

W.E.T. Automotive Systems AG, for example, does durability testing using a KUKA KR 150 robot that is flexible, programmable, and allows repeatable stress at precise loads and positions. KUKA’s Occubot VI, for example, uses hydraulic and pneumatic drives to simulate ingress/egress, the strong pull stations and vibrations that occur during driving, and more.

The following video shows automated testing of a car seat: