Conventional recycled leather typically combines shredded leather scraps and fibers with non-biodegradable binders like PU and PVC. In contrast, reProLeather transforms leather waste into a material that is claimed to be recyclable and biodegradable, closely resembling new leather.

The technology is being developed by scientists at the Hong Kong Institute of Textiles and Apparel (HKRITA) with support from the H&M Foundation in Sweden.

Transforming Waste into Recyclable Leather

The fashion industry is increasingly seeking recycled materials to reduce waste and conserve resources. However, recycling specific materials, such as leather waste, can be challenging due to the presence of harmful chemical residues like chromium VI, a byproduct of the tanning process, which persists in conventional recycling processes.

ReProLeather has introduced an innovative process to extract chromium VI from shredded leather fibers while developing a bio-based alternative to PU and PVC binders. This breakthrough has resulted in a new type of recycled leather that is both biodegradable and recyclable.

The Pioneering Science Behind reProLeather

The conversion process begins with the thorough shredding of post-consumer leather goods, breaking down the leather into its fundamental component: collagen fibers. Toxic chromium used in the production of these goods is removed by converting it into a soluble salt.

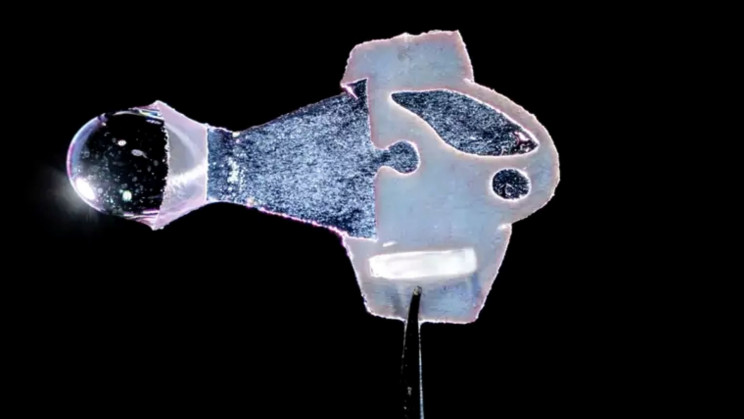

The purified fibers are then mixed with sugars and proteins to create a gel-like mixture, which is then spread into a sheet. Simultaneously, a protein fiber skeleton is placed on top of the mixture during the drying and curing process, allowing cellulose fibers to interconnect.

The final product closely resembles new leather in terms of its appearance, texture, and strength. Unlike traditional bonded leather, it can be recycled or left to naturally biodegrade when disposed of.