Scientists are looking to hydrogen as a promising source of clean fuel, also known as green hydrogen.

Green hydrogen is hydrogen gas produced through a process that uses renewable energy sources, such as wind, solar, or hydropower, to extract hydrogen from water or other sustainable feedstocks.

These methods are considered “green” as they generate minimal or no greenhouse gas emissions, making them an eco-friendly alternative to conventional hydrogen production methods, which often rely on fossil fuels.

Making Green Hydrogen

The cleanest process for producing green hydrogen is electrolysis. In that, electricity is passed through water to split it into its constituent elements, hydrogen, and oxygen. The electricity used in this process also can come from renewable sources to ensure that the overall carbon footprint of the hydrogen production is very low or even zero.

Moreover, green hydrogen can also effectively supplement intermittent energy sources such as solar and wind. It is expected that green hydrogen can displace natural gas-based hydrogen, generated by methane steam reforming. Eventually, the production of green hydrogen can eliminate the carbon footprint of the hydrogen industry.

A Way to Harness Green Hydrogen

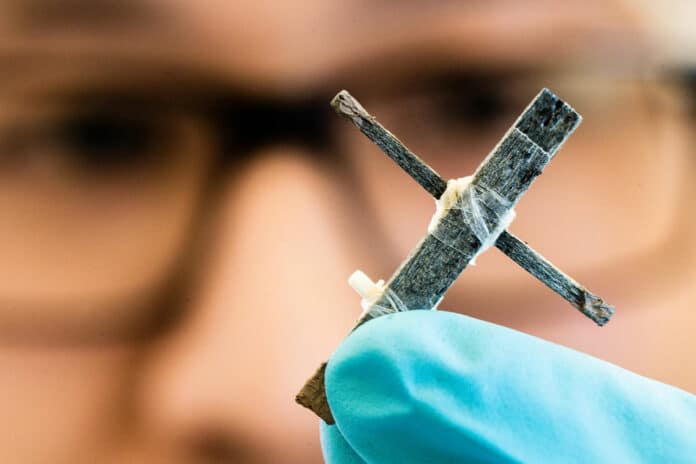

Travis Williams, a chemist at the USC Loker Hydrocarbon Research Institute, has developed a “hydrogen on-demand” reactor to simplify and cost-effectively the transportation of hydrogen.

It can’t be denied that hydrogen’s uses are vast. While gasoline releases carbon dioxide when burned, hydrogen combustion produces only water vapor. Hydrogen has the potential to transform many sectors from transportation to biofuels, fertilizers, and environmentally benign chemicals.

It is converted to water and electricity in a fuel cell to fuel zero-emission fuel cell electric vehicles (FCEVs). In addition, hydrogen is also a key ingredient in a range of industrial processes such as petroleum refining, or metal treatment. However, the high cost and logistical complexity of transporting hydrogen create many cost barriers.

The reactor is designed to transport hydrogen in a more affordable liquid form called formic acid, which can be transported to the desired location and converted back into hydrogen. Hence, this technology allows for the seamless mobility of hydrogen to ensure it can be readily converted into a usable form wherever and whenever it is needed.