Canadian researchers at the McGill University in Saskatchewan have presented a novel method for growing highly-tailored synthetic bone tissue at any shape and density, essentially paving the way to helping patients who suffer from any form of skeletal damage.

The team of scientists consisting of experts from various disciplines used porous graphene oxide as their structural scaffold and filled it with an emulsion of water and oil. Once stem cells are placed on it, they automatically transform into osteoblasts, which are natural bone matrix synthesizers.

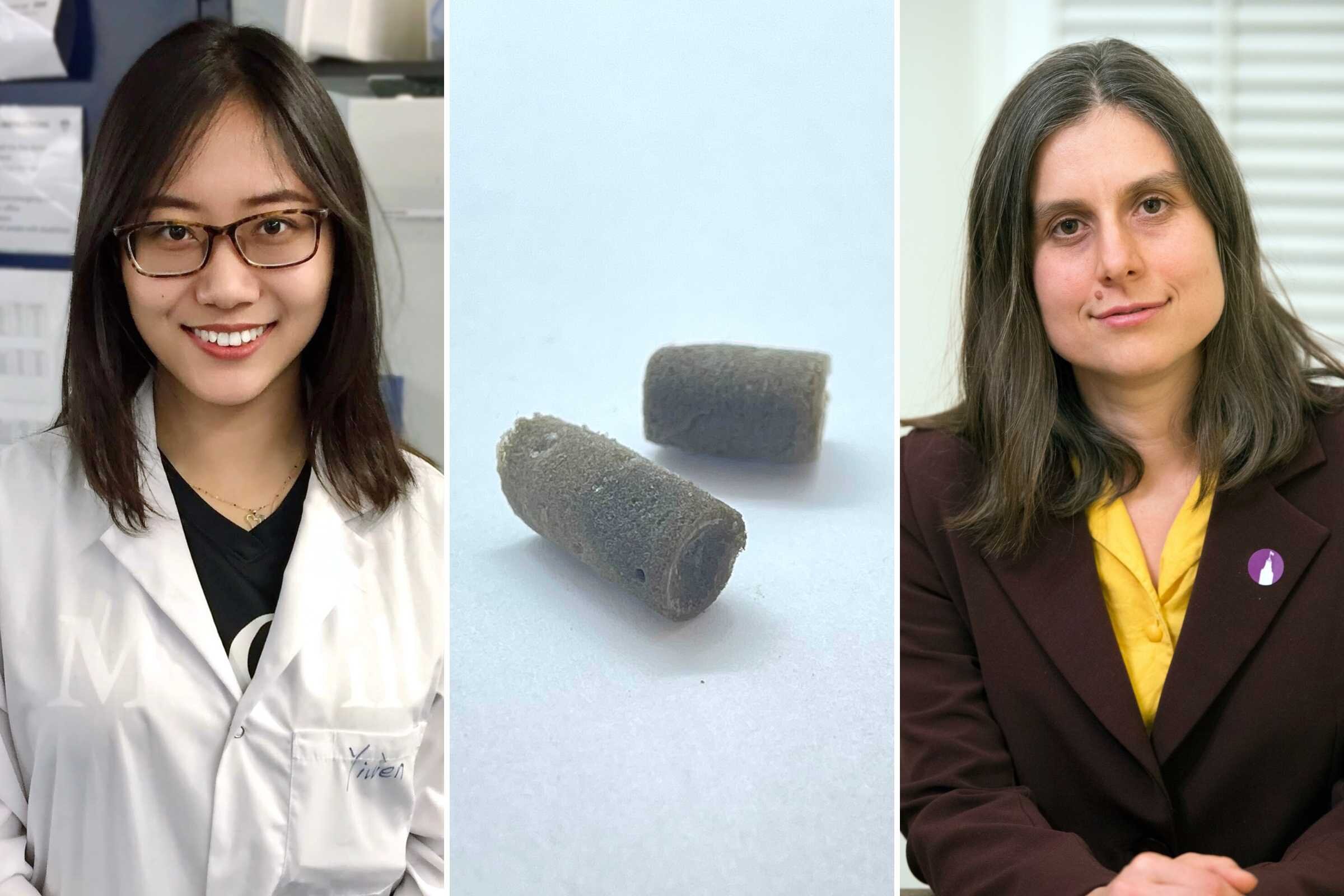

Image Credit: Canadian Light Source

The tests involved two different freezing temperatures for the units, resulting in two distinct pore sizes, so the team produced light and heavy bone tissue that can help in various applications.

This new approach doesn’t just replace synthetics and 3D printed solutions in terms of practicality, but also offers a higher-quality result for the patient. Having genuine bone replacement comes with a set of advantages over any other solution, as the specific mineralization rates during the bone synthesis give the parts particular mechanical properties, most notably, an ideal balance between strength and elasticity.

Of course, stem cells aren’t easy to come by, nor are they inexpensive to source, maintain, and use in treatments, but this new approach would bring next-level treatment results for patients who are willing to cover the cost.

For research purposes, the team used mouse bone marrow, which may be used in humans, but hasn’t been extensively tested yet. From the preliminary results, the scaffolds and the mouse stem cells appear completely biocompatible.

All that said, seeing this synthetic bone growth in actual clinical application is still several years away, but it gives all medical researchers a better understanding of cell morphing, synchrotron light applications, tissue growth simulation, and even chemical and drug interaction. So even if the method is still far from seeing real action, it’s still crucial for current research.