Researchers at the University of Georgia developed a “super-foam” with two very valuable potential applications. This multipurpose foam material could not only be used to reduce infections caused by implanted medical devices, but also be used to clean up oil spills.

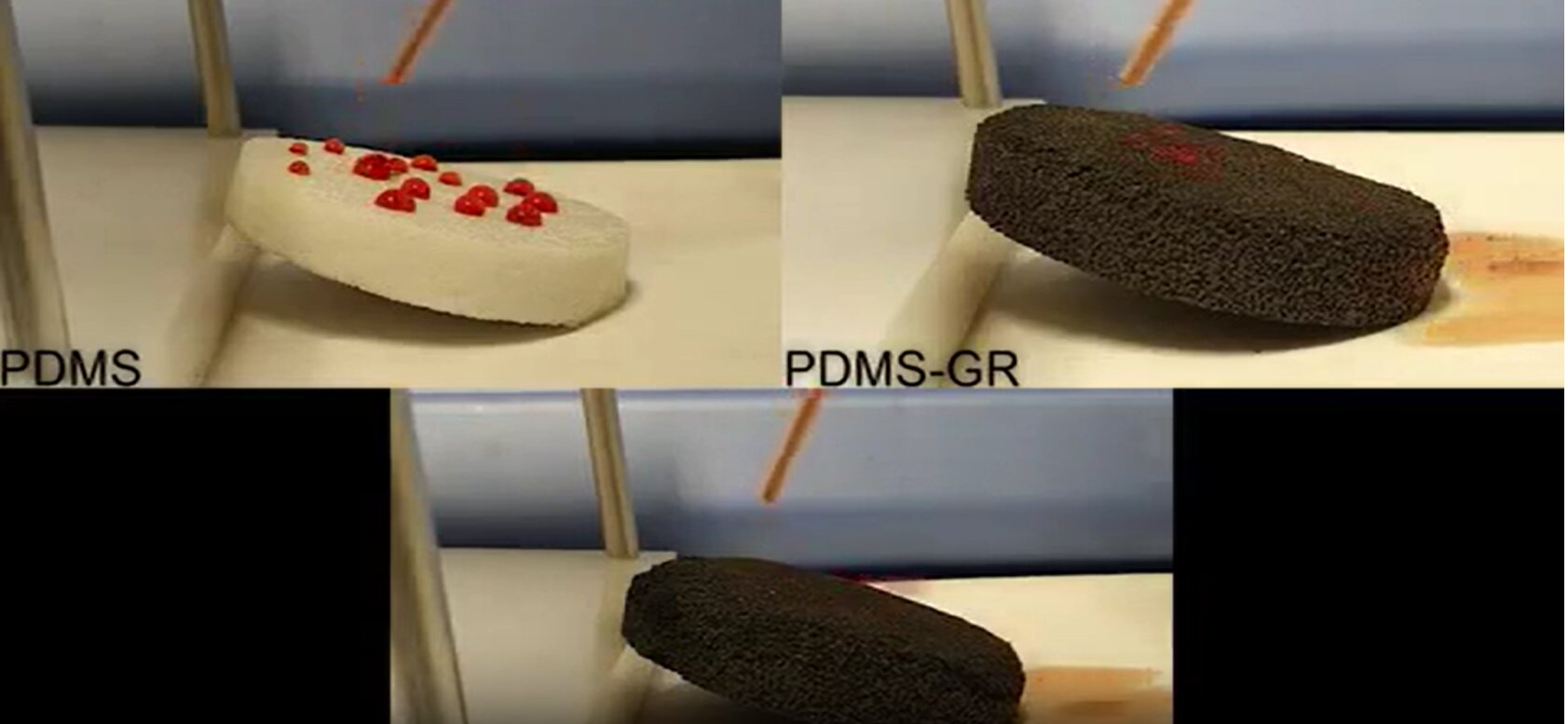

This three-dimensional porous foam is the integration of graphene nanoplatelets and antibacterial copper microparticles into a poly(dimethylsiloxane) (PDMS) framework. This helped in giving a foam course, a porous structure that is water-repellent and exhibits antimicrobial and oil-water separation properties.

“Making a multifunctional and versatile surface is an extremely challenging task,” said study author Hitesh Handa. “You can find a surface that is only antimicrobial, or you can find one that can only prevent blood clotting. To be able to fabricate materials that are anticlotting, antimicrobial and antifouling is a significant improvement on current standards.”

When researchers placed this 3D sponge in water polluted with oil, it adsorbed the oil out of the mixture. After that oil can be easily removed, and the sponge can be reused multiple times to take up more oil.

Then researchers placed the sponge into various water mixtures, including chloroform, hydrochloric acid, and other organic particles. The foam not only absorbed and removed the organic pollutants from the water but also killed bacteria making contact with the foam in the water itself.

“Current medical devices are prone to contamination,” said Handa. “When you put any medical device into the body, proteins are the first thing to stick to a surface, and they act like a glue that allows blood or bacteria to adhere. So, if we can stop the protein adsorption, half the battle is won.”