Rapid prototyping is an innovative process that revolutionizes how products are designed and developed. From concept to completion, it has transformed the speed and accuracy with which businesses can develop products.

This creative process has become an essential part of development, allowing companies to quickly design and test prototypes of their products before they go into production. But what exactly is rapid prototyping, and how does it work? Read on to find out!

What is Rapid Prototyping?

Rapid prototyping is creating a physical or digital design representation to test it. This process is used to verify the functionality of the invention, identify problems, and explore different concepts before producing a final product.

When it comes to product design, Rapid Prototyping allows engineers and designers to save time and money by creating a prototype faster than traditional methods. Once a prototype is built, it can be tested and modified to refine the design. This helps to ensure product quality and reliability.

Now that we understand what Rapid Prototyping is, let’s look at the different stages involved in the process.

Understanding the Different Stages of Rapid Prototyping

Prototyping has opened up a world of possibilities for product development. By allowing designers and engineers to create and test prototypes quickly, companies can now develop higher-quality products much faster and more efficiently. So if you’re looking to develop a new product, start by exploring the different stages of rapid prototyping and see how it can help you create better products faster and cheaper.

Stage 1: Conceptualization

This stage consists of brainstorming, researching feasible solutions, and evaluating the concepts and ideas. Brainstorming can help identify potential solutions, test ideas, and narrow down the best options. Feasibility analysis helps businesses identify if the answers are realistic, possible, and commercially viable. Creating a concept is essential to identify any risks and ensure the product is a viable solution to the problem.

Stage 2: Model Creation

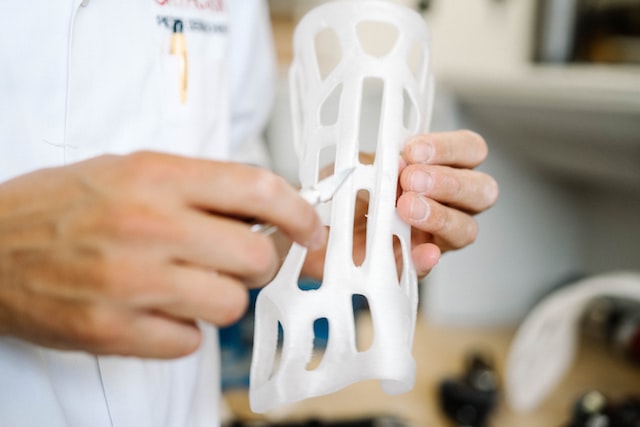

It involves designing the concept, selecting materials, and testing the design. Developers can use computer-aided design (CAD) to help create the model and make changes quickly. A CAD services company can provide comprehensive training to support this process. Prototype material selection is also crucial as it determines the prototype’s strength, durability, and cost.

Stage 3: Prototype Testing

Testing the prototype includes verifying its functions and validating that the concept and design work together as intended. This stage helps identify potential issues with the prototype and make improvements before the final product is released.

At its core, rapid prototyping is the process of creating a physical model of an idea or concept quickly and efficiently. The process involves creating a 3D model from a 2D drawing or design using 3D printing. Once the model is printed, it can be tested, evaluated, and further developed.

Quick Benefits of Implementing Prototype Testing in Product Development

-

Reduced Time to Market

It allows organizations to quickly develop and test products, reducing the time to market. This will enable companies to get their products to market faster and stay ahead of their competition. -

Cost Savings

It eliminates the need for costly tooling and production runs, allowing businesses to save money and invest it in other areas of their business. -

Improved Quality

It allows companies to identify and fix design flaws before they become costly problems. This helps to ensure that the final product is of the highest quality. -

Increased Flexibility

Companies can quickly adapt to changing customer needs and market trends. This helps establishments stay competitive and remain agile in a rapidly changing market. -

Improved Collaboration

Organizations can quickly share ideas and collaborate with other teams. This helps them confirm that the best ideas are implemented and that the final product meets the customer’s needs.

Takeaway

From the initial idea to the final product, prototyping is a multi-step process that requires careful planning and execution. With many advantages, Rapid Prototyping will indeed become a key aspect of product development process for years to come.