3D printing technologies have shown wonders in every field of life. Now you can live in a 3D-printed house, eat 3D-printed meat, play with 3D printed toys and wear even 3D printed jewelry.

Although 3D printing is very advanced, it is a very slow process. But soon we will have a quicker and more effective method. As researchers from the University at Buffalo have discovered a 3D printing technique that’s 10 to 50 times faster than standard methods.

Ruogang Zhao, associate professor of biomedical engineering, said, “The technology we’ve developed is 10-50 times faster than the industry standard, and it works with large sample sizes that have been very difficult to achieve previously,”

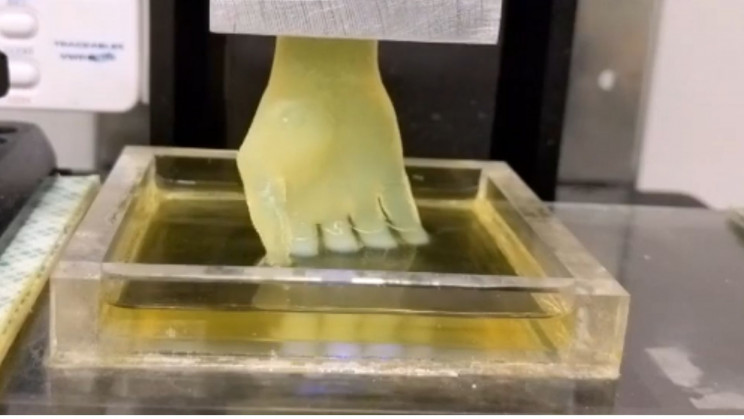

Using the standard method of 3D printing, a tiny synthetic hand takes about six hours to print. Now, researchers have released a seven-second video that is sped up from 19 minutes. They showed a full hand being printed at once.

By demonstrating this, University at Buffalo engineers say this is progress toward 3D-printed human tissue and organs. They are hopeful that this biotechnology could eventually save lives lost due to the shortage of donor organs.

This approach makes use of a combination of 3-D printing technique called stereolithography and jelly-like materials known as hydrogels.

Co-lead author, Chi Zhou, said, “Our method allows for the rapid printing of centimeter-sized hydrogel models. It significantly reduces part deformation and cellular injuries caused by the prolonged exposure to the environmental stresses you commonly see in conventional 3-D printing methods,”

According to scientists, this technique is suitable for printing cells with embedded blood vessel networks. They foresee this technology is going to be a central part of the production of 3D-printed human tissue and organs.