Weighing up the advantages and disadvantages of investing in second hand industrial equipment over a brand-new equivalent is important, since it will allow you to make an informed decision during the procurement process.

To help you come to the correct conclusion for your business, here is a look at the two sides of this argument.

Availability & accessibility

Before you even consider the issue of cost, one of the biggest complications that comes with buying new equipment is that it may not even be available when you need it. Manufacturers can take months to fulfil orders depending on the size and complexity of the kit, and there may be other complications to consider, such as if the option you desire has been significantly altered from the specification you require or discontinued altogether.

Meanwhile according to Revelation Machinery, online marketplaces for used industrial equipment are packed with options that are available immediately and also accessible to buyers in many different regions. This means you can get the exact model you need in a short time frame even if it is no longer being made by the original brand.

Pricing

The undeniable reality of the used machinery market is that buyers will be able to pick up equipment of all sorts for far less than they would pay when choosing a brand new counterpart.

Of course this is not universally true, as certain types of kit can maintain its value very well over time and rarer examples may even become more expensive, creating something of a conundrum.

Ultimately you need to match your budget to your needs and make sure that you check the market value of used equipment carefully before you commit. You should also consider the perks that come with a new purchase that add value over time, such as extended warranties from the original manufacturer that could be hugely beneficial in the case that a fault develops.

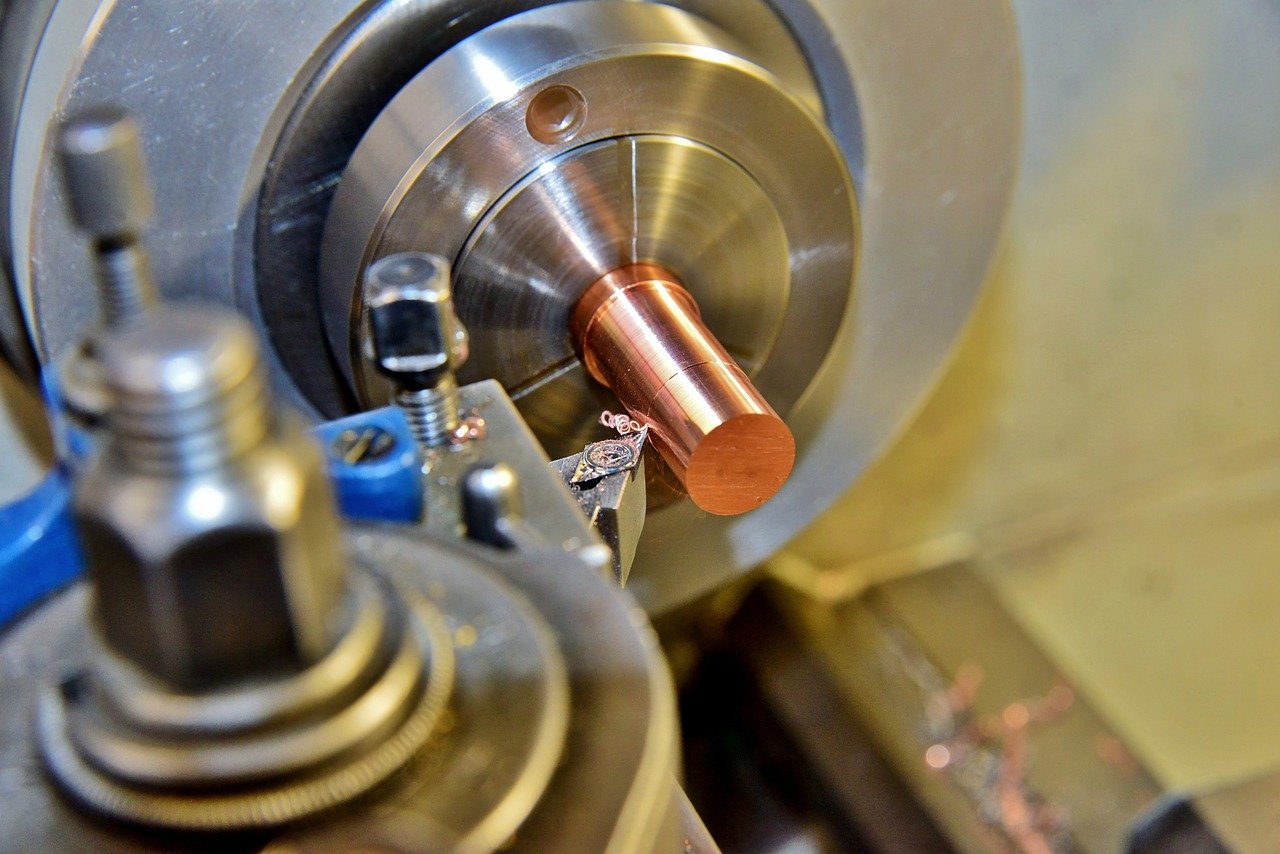

Wear and tear

Obviously if you buy new equipment, it will be pristine when you first install it and should be able to survive for long periods so long as it is properly used and maintained. Conversely the condition of used machinery can vary wildly and it may not be obvious from the outside the extent to which a particular bit of kit is still in good shape.

When buying used, getting an inspection is often advisable to allay any fears about its condition. You can also often tell whether it has been cared for simply by seeing whether the seller has bothered to clean it up and make it look appealing. Since downtime can cost you a lot of cash, you want to make sure that your equipment is sufficiently reliable whether it is new or used.

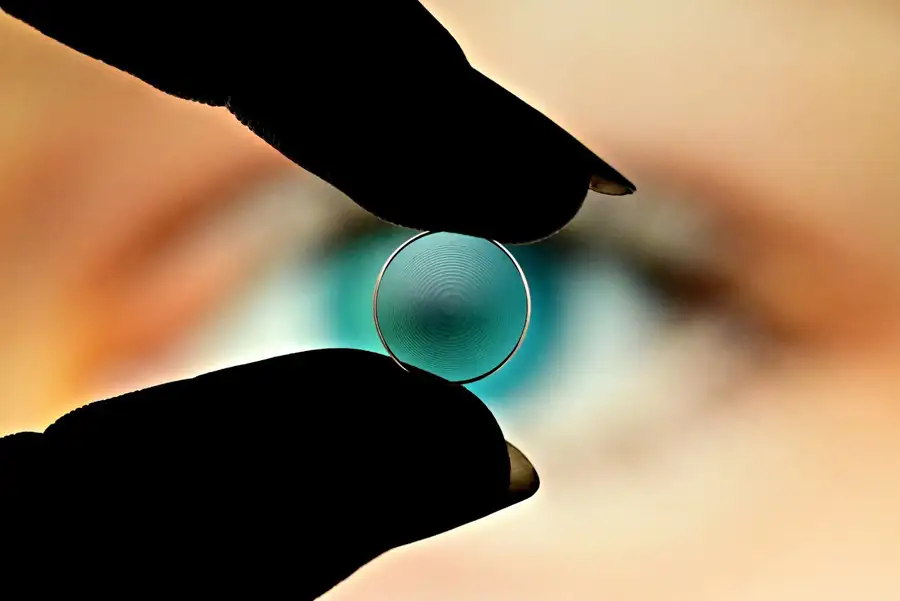

Parts

This is another important area that you should not overlook when ordering any kind of industrial equipment. It is not just a matter of making sure that you can carry out maintenance on a regular basis, but taking steps to provide the right parts to fix issues as and when they arise.

With a new machine, parts should be available from the manufacturer as part of its support program. With a used model, sourcing parts can be trickier, depending on the age of the unit as well as the make and model.

There are obstacles in either case, of course, so once again it all comes down to making sure that you do enough research and do not make assumptions whichever route you choose to take. This will allow you to procure the right equipment regardless of your circumstances.