Omron’s new E3AS Series of reflective-type photoelectric sensors open up new possibilities in the industrial production field. These sensors are used in a wide range of applications, and this is why the launch of such products is so groundbreaking. More specifically, they are used in assembly lines, conveyor lines, etc., detecting faulty products, sensing short distances, and more.

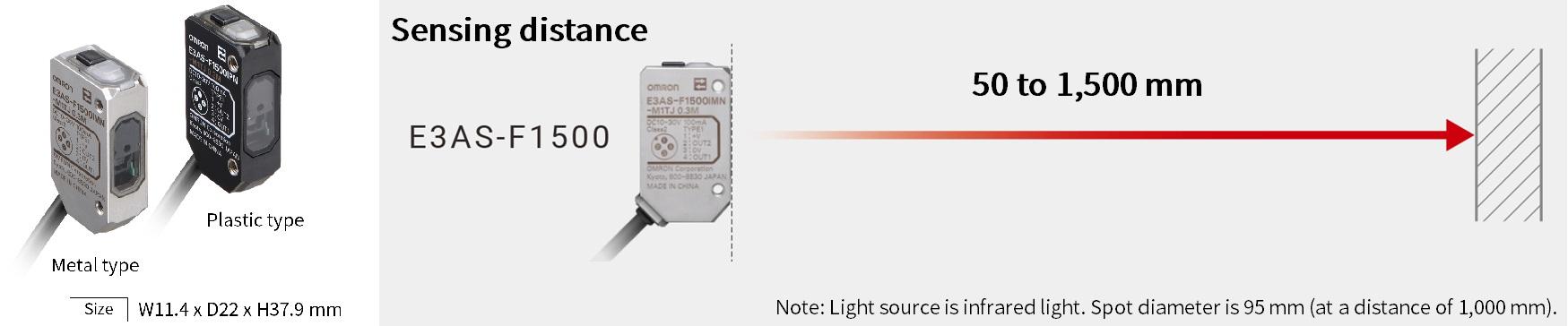

The key difference with the new generation is that they increase the maximum sensing distance range from 300 mm in the previous model, to a whopping 1500 mm.

This provides a new level of versatility for production engineers and technicians, who will be freed of numerous limitations. For example, dealing with placement of the sensors and their capacity to withstand the environmental conditions so close to the action will no longer be a thing. Moreover, the minimum sensing distance of E3AS is 50 mm, which also eliminates the need for using various different “specialized” sensors.

The method of detection for the new E3AS is called “time-of-flight”. The sensor measures the time elapsed between sending a signal and detecting its reflection, similarly to how radars work. This is more reliable than the “triangulation” method that is generally used in the field, and which yields varying measurements depending on the surface reflectiveness and other properties. Engineers adjust triangulation sensors accordingly, but this is not needed with the new E3AS.

Omron also points out that the new sensors are small enough to be installed in AGVs (automatic guided vehicle), which are extensively used in warehouses and factories today. The same applies to confined space installations.

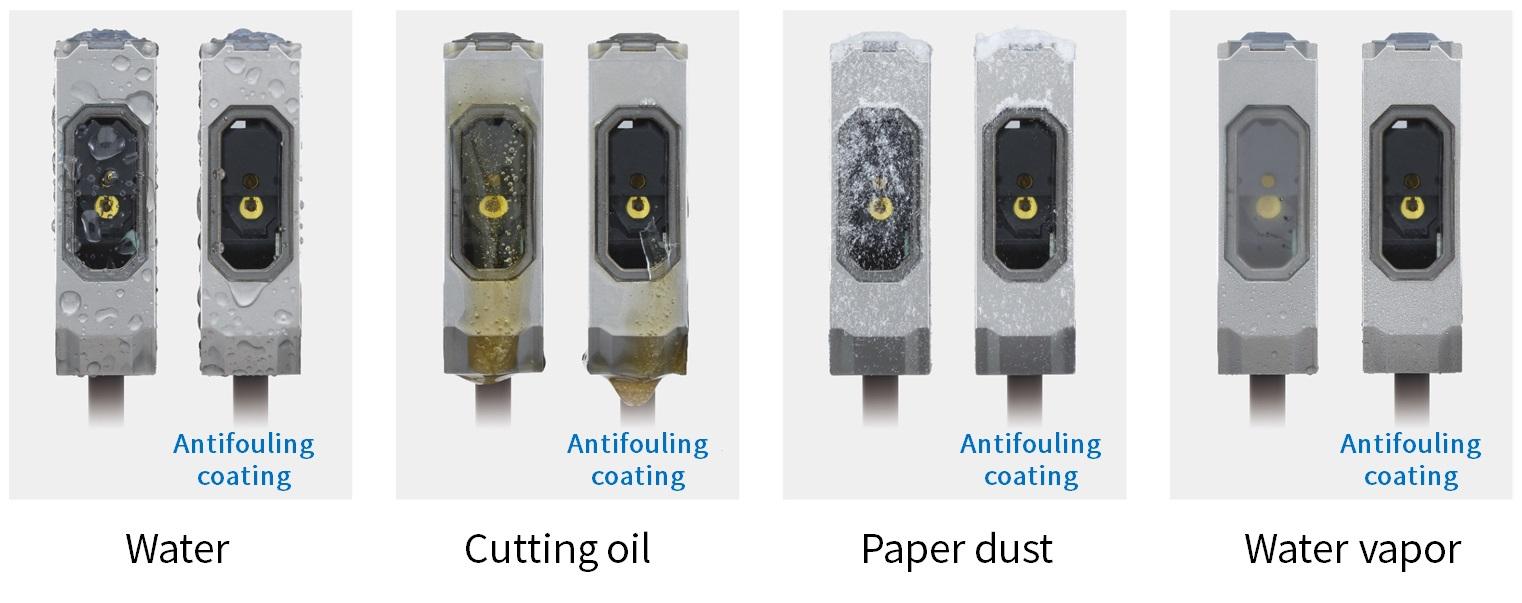

Finally, Omron also mentions a new “antifouling coating” that helps prevent contamination on the sensing surface, reducing downtimes and production hiccups. To complement its robustness, there’s an IP69K and IP69G water pressure, high temperature, and oil resistance.