A barcode sticker that you often see on the merchandise might look ugly, but it presents precious info about the product. However, these barcode stickers can be damaged easily and cause problems while scanning.

Now a team of researchers from MIT has developed 3D-printed tags to classify and store data on products. These machine-readable tags can identify and track objects but are invisible to the bare eye.

The MIT team has developed a software “user interface” that decides exactly what the tag should look like and where it should be placed within a particular object.

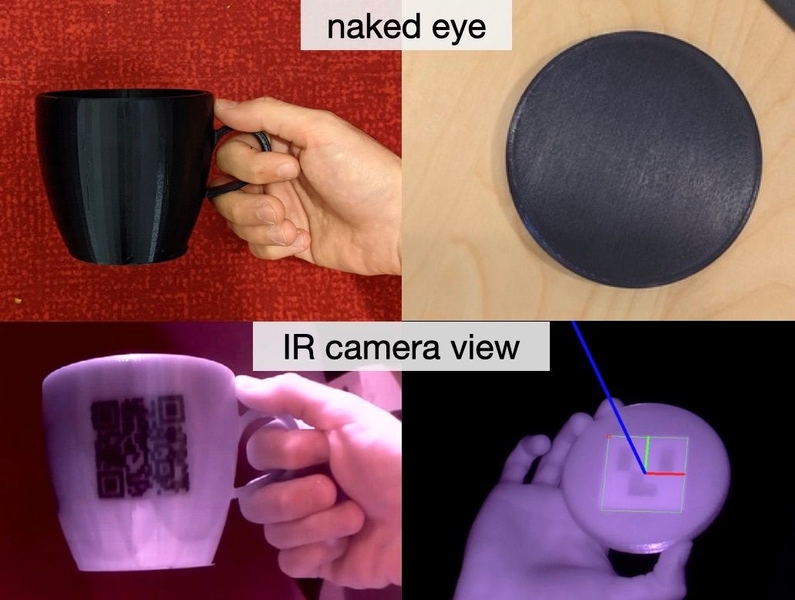

An existing commercial 3D-printing plastic filament is incorporated into the system. Although opaque to visible light, it lets infrared light pass through it. Multiple 3D printed tags could be placed throughout an object, making it easy to access information from any angle.

Data can be embedded in either of two ways

One approach includes carving a pattern of tiny air gaps out of a layer of plastic, which is covered with a protective outer layer. The gaps represent ones and zeroes, read by an infrared digital camera as binary codes.

Another approach includes creating extra conventional barcodes or QR codes using a second plastic, opaque to infrared light. Once more these are covered with an outer layer of plastic. They are visible on exposure to infrared light and imaged by an infrared-sensitive digital camera.