Owners of older car models always ramble about two things, a.) the amazing joy that stems from the pure driving experience of old classics, and b.) the distressing process of having to find spare parts, painstakingly searching and sourcing them from the most obscure places. Simply put, car manufacturers cannot continue producing spare parts forever, as the number of old models still needing these parts is steadily thinning, so making them is no longer economically sustainable.

Nissan has launched a partnership with SOLIZE and HP, hoping to put an end to this problem by 3D printing parts for older models like the various previous generations (R32, R33, and R34) of the Skyline GT-R for example. 3D printing spare car parts can help passionate car enthusiasts break free from the fear that underpins owning a classic car, and remain assured that they will find any part they need at a reasonable price. That doesn’t mean that they are going to be cheap, but at least you’ll be able to find them and they are going to be in accordance with the OEM specifications.

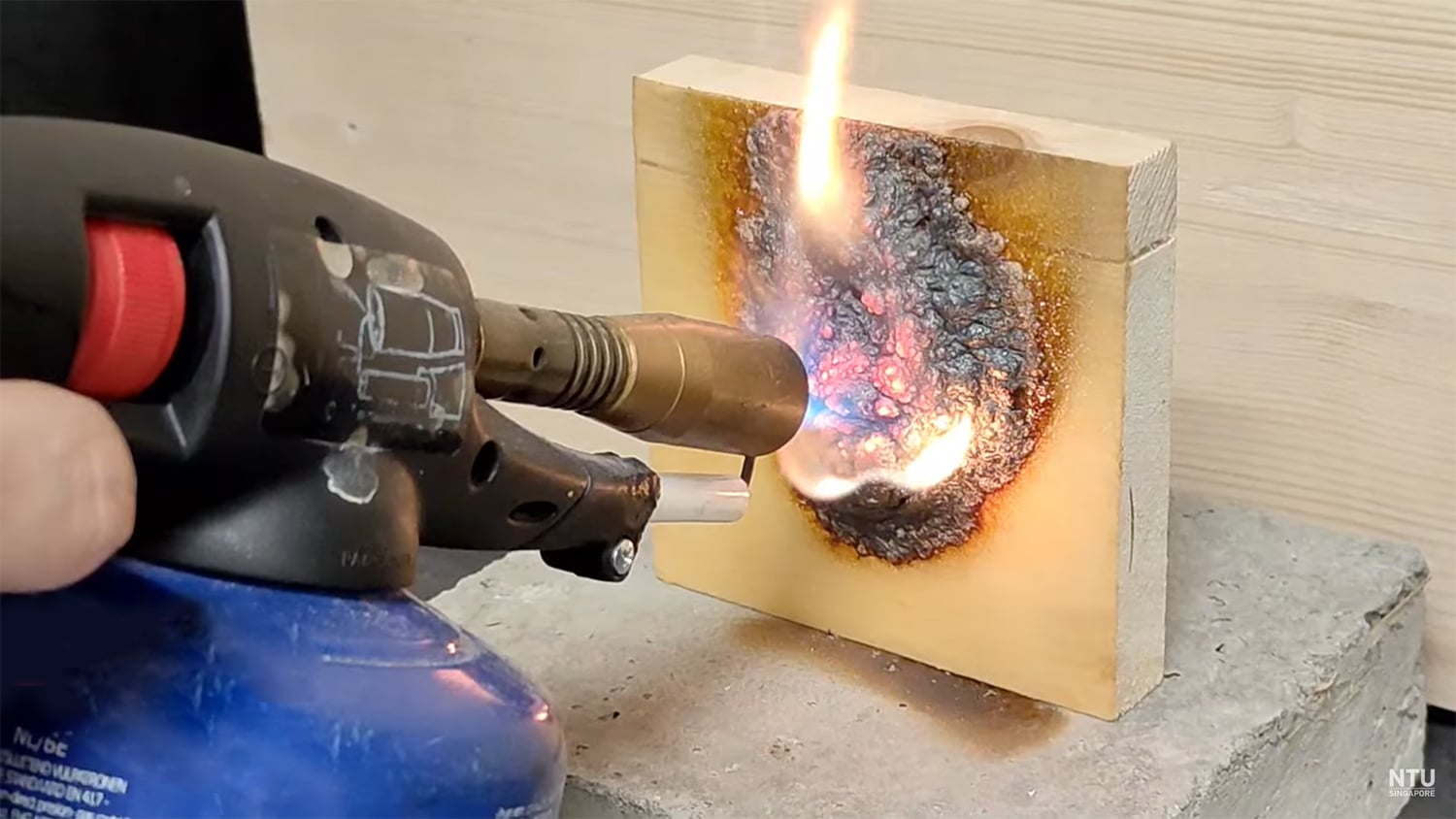

The technology that will make this possible is HP’s Multi Jet Fusion (MJF), which can produce highly accurate and also durable parts at relatively fast speeds. For starters, the three entities will determine suitable parts for a first wave of testing, so they will start with plastics that can withstand high temperatures or have good mechanical properties. From crank pulleys to bumper clips, and from body panels to harness protectors, there are over 300 spare parts that will take part in this new program initially.

From there, metallic alloys and powders may open up the spectrum of available discontinued parts, but this will come at a later stage and on the basis of demand, and what makes economical sense. Definitely, Nissan’s spare parts project will have the attention of other automakers too, who could follow a similar approach in order to cover low demand on key parts of models that are historically important for their brand.