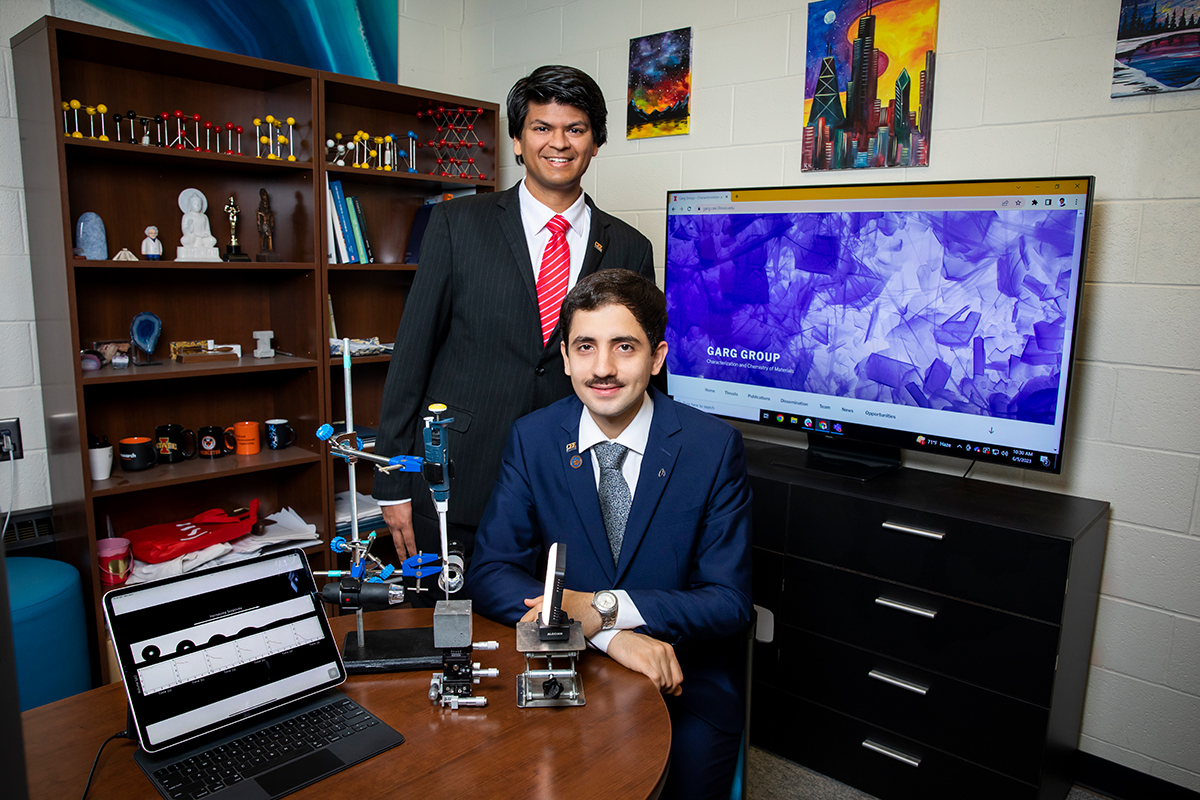

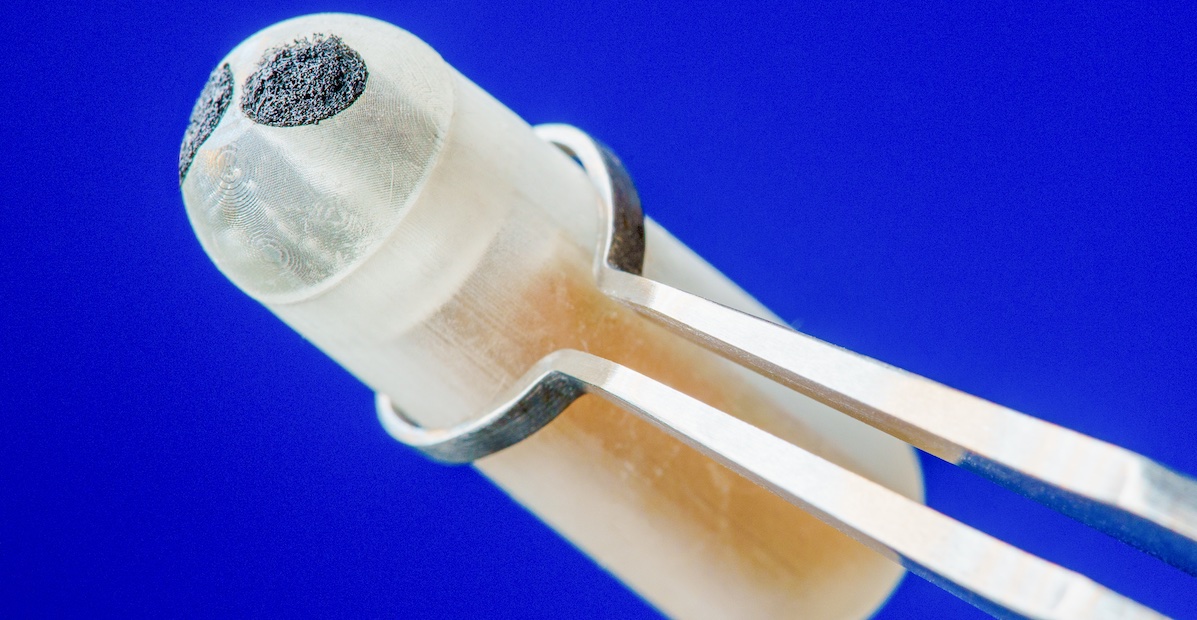

Researchers at the University of Illinois Urbana-Champaign created a test that is able to predict cement durability in seconds to minutes. This is achieved by measuring the behavior of water droplets on cement surfaces and utilizing computer vision on a device. The study was published on July 5, 2023 in npj Materials Degradation, named “Rapid prediction of cementitious initial sorptivity via surface wettability”. The research was also supported by the Department of Civil and Environmental Engineering at Illinois.

This study has the potential to help the cement industry as it enables fast and automated quality control, since current methods for cement durability last for hours. As said by Illinois civil and environmental engineering professor Nishant Garg, “Concrete is one of the most consumed materials on our planet, second only to water,”, adding that “The concrete used to build our infrastructure degrades over time via exposure to deicing salts; freeze and thaw cycles; and ingress of water – all of which can lead to corrosion of the rebar that is used to strengthen the structures. Ultimately, this leads to failure, sometimes catastrophically, as seen in the 2021 condominium collapse in Surfside, Florida, where 98 lives were lost.”

The currently utilized standard test is ASTM C1585, which is performed in a lab. Here, a sample of concrete is exposed to water, and the weight change is observed for several hours or even days, as water absorption is related to the durability of cement. In addition, the engineering team discovered that the initial angle at which the water droplets contact the cement surface is also important. The researchers are also working on enabling the testing of more complex concrete varieties and mortars.

Prof. Garg also added that “The key takeaway from the study is that testing the durability of building materials is very slow, tedious and labor-intensive,”, and “With the availability of technologies like computer vision and analysis, we can develop tests that are faster, automated and convenient.”