Researchers from the Beckman Institute developed a new ink for 3D printing that is able to change colors. This technique utilizes ultraviolet (UV) light to alter the surface structure of the material. Hence, this enables the media to change colors and 3D-print multiple colors from a single ink in one print job.

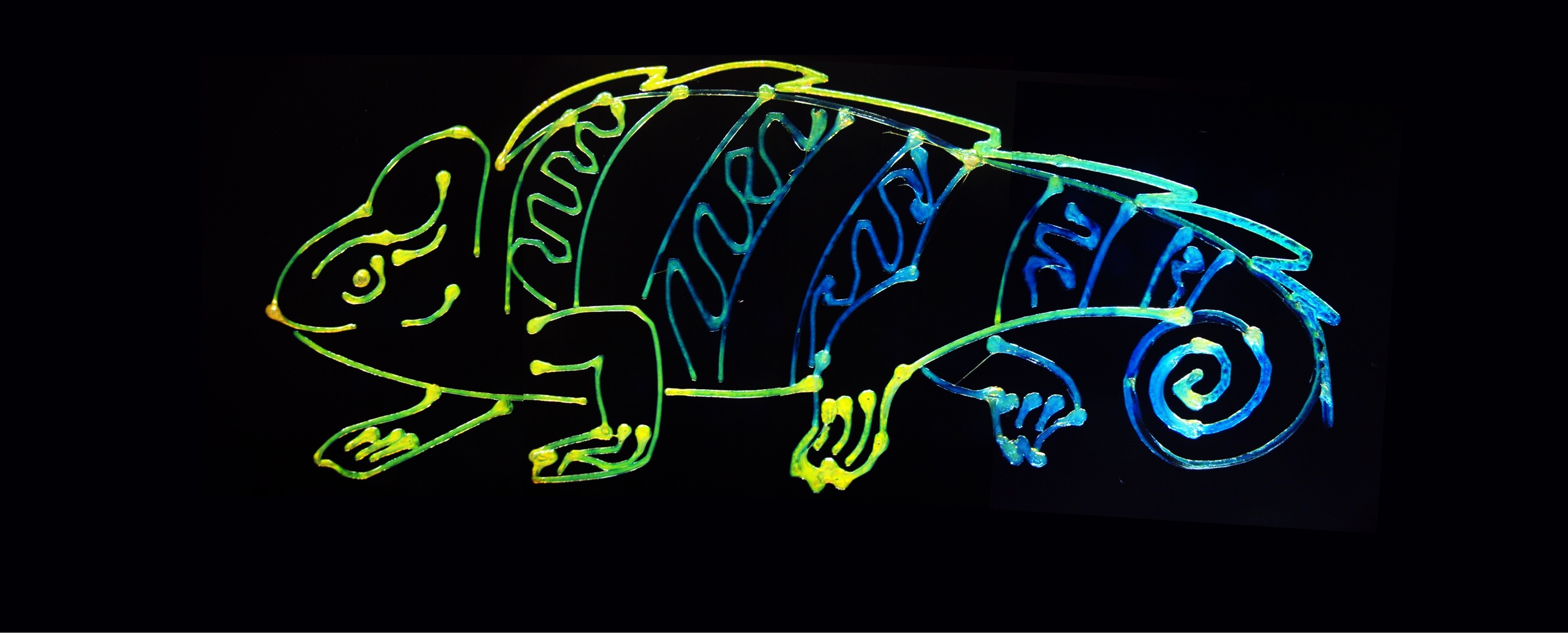

Moreover, this approach may potentially create more sustainable colors, that are in the visible wavelength spectrum (deep blue to orange). The scientists were inspired by the chameleons’ color-changing ability, and a multicolored chameleon was printed as a demonstration.

Ying Diao, an associate professor of chemistry and chemical and biomolecular engineering at the University of Illinois Urbana-Champaign and a researcher at the Beckman Institute for Advanced Science and Technology, said, “By designing new chemistries and printing processes, we can modulate structural color on the fly to produce color gradients not possible before,”

The resulting printing ink is known as “photo-cross-linkable bottlebrush block copolymer solution”. When exposed to UV light directly after being extruded from the printing nozzle and depending on factors such as extrusion speed, the intensity of UV light, and the print head motion, the ink solidifies and appears in colors within the visible light spectrum.

Sanghyun Jeon, lead author and a graduate student in the Diao Lab, said, “Unlike traditional colors which come from chemical pigments or dyes that absorb light, the structural colors abundant in many biological systems come from nano-textured surfaces that interfere with visible light. This makes them more vibrant and potentially more sustainable,”

Charles Sing, co-author and associate professor of chemical and biomolecular engineering and materials science and engineering, said, “Only by working together could we design this system at the molecular level to yield such fascinating properties,”

The paper is published in the journal PNAS, and is titled “Direct-Ink-Write Crosslinkable Bottlebrush Block Polymers for On-the-fly Control of Structural Color”