While Lithium is currently the target of the mining industry because of the skyrocketing increasing demand for electric vehicle batteries, rubidium is used in technologies such as atomic clocks, motion sensors, signal generators, and GPS equipment. These technologies have to rely on the hyperfine transition of electrons in rubidium atoms to keep time.

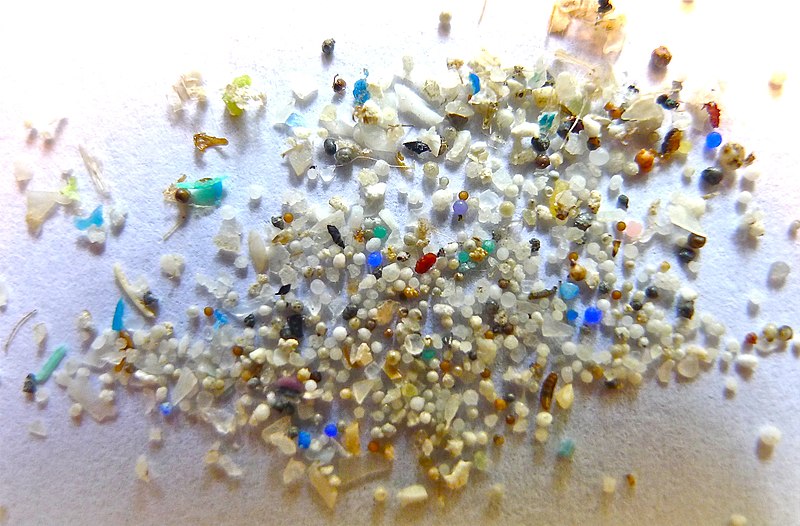

Like lithium, rubidium is mined from rock or pumped to the surface in briny groundwater. If rubidium was previously often seen as an impurity that needed to be removed from a lithium deposit, new research on extracting this element can put it to wider use in high-tech industries.

Researchers at Edith Cowan University (ECU) have partnered with the company Everest Metals Corporation to get rubidium out of the rocky samples collected at the Mt. Edon pegmatite field using a new direct rubidium extraction technique. They recovered 91 percent of the rubidium from rock samples, according to a report in December of last year.

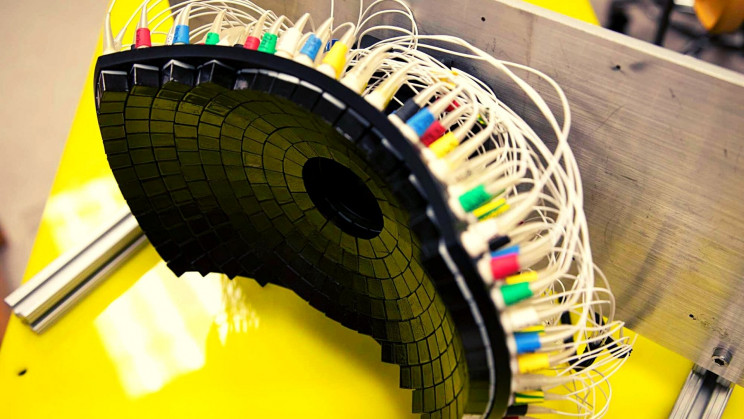

Amir Razmjou, the lead investigator on the project and an associate professor at ECU, said the team used the technique to recycle water for the process. Water recycling is what makes the extraction method more sustainable than other extraction techniques, which is an adaptation of membrane technology used for water desalination.

To date, there’s not much information available about the specific chemicals used in the extraction technique, which Everest Metals and ECU are in the process of filing a patent. However, the method generally follows three main steps, including crushing the rock samples, dissolving the mineral in acid, and purifying rubidium and lithium from the acidic slurry.

In November of 2024, researchers from Tianjin University in China also developed a technique to extract rubidium from solid potassium chloride salt, which forms after brine has dried.

By extracting rubidium from solid salts and limiting the amount of water in the process, the researchers used 98 percent less energy than the techniques that extract rubidium directly from watery brine.

Although the U.S. Geological Survey’s latest data published in 2024 reported there are no active mining sites of rubidium, Everest Metals expects the rubidium market to grow from 6.36 tonnes in 2023 to 7.94 tonnes in 2028.