NASA has developed a metal alloy that is 1,000 times stronger than current state-of-the-art materials used in aviation and space exploration.

To maximize spacecraft longevity and for countering the formidable challenges of launching missions, strong and long-lasting materials are needed.

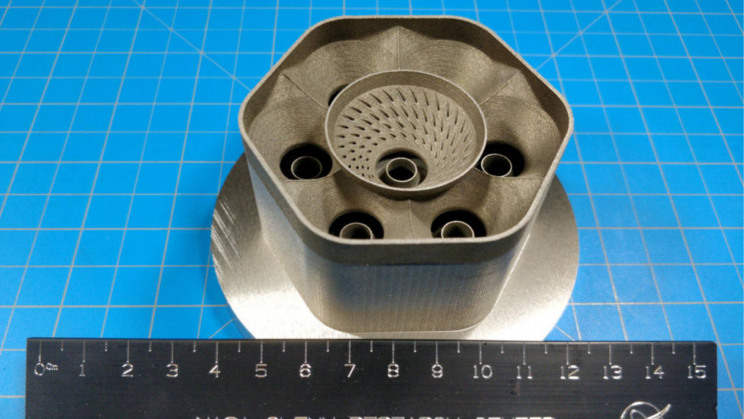

Now NASA innovators have created the material dubbed GRX-810. It is an alloy created using 3D printing. Researchers also employed a technique called thermodynamic modeling while creating this alloy.

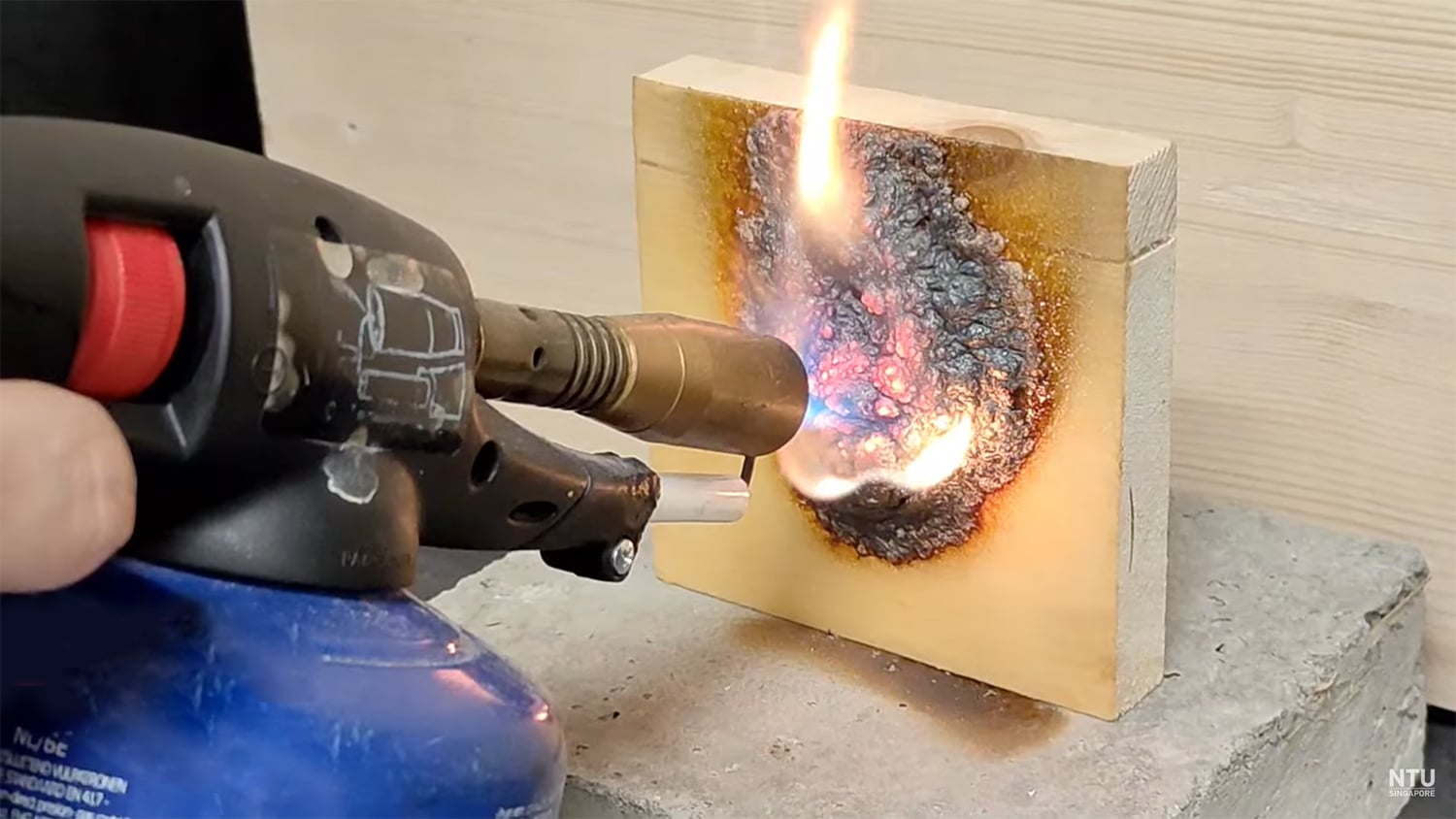

GRX-810 is prepared from oxide dispersion strengthened (ODS) alloy that could bear temperatures beyond 2000 °F (1093 °C). ODS alloy is usually used in high-temperature settings such as turbines and heat-exchange tubes.

In comparison to contemporary materials, GRX-810 has

- Twice the strength to resist fracturing.

- 1,000 times the durability under stress at high temperatures.

- It is more malleable, and also has three and a half times the flexibility to stretch/bend before fracturing.

- It is relatively cost-effective and lightweight.

Dale Hopkins, deputy project manager of NASA’s Transformational Tools and Technologies project, said, “This breakthrough is revolutionary for materials development. New types of stronger and more lightweight materials play a key role as NASA aims to change the future of flight,”

“Previously, an increase in tensile strength usually lowered a material’s ability to stretch and bend before breaking, which is why our new alloy is remarkable.”