Boiling water is big business. From Coal plants to concentrating solar power plants, all work by turning water into steam and using that steam to generate electricity.

Any improvements in the efficiency of this process can have a tremendous impact on the overall amount of energy used every day.

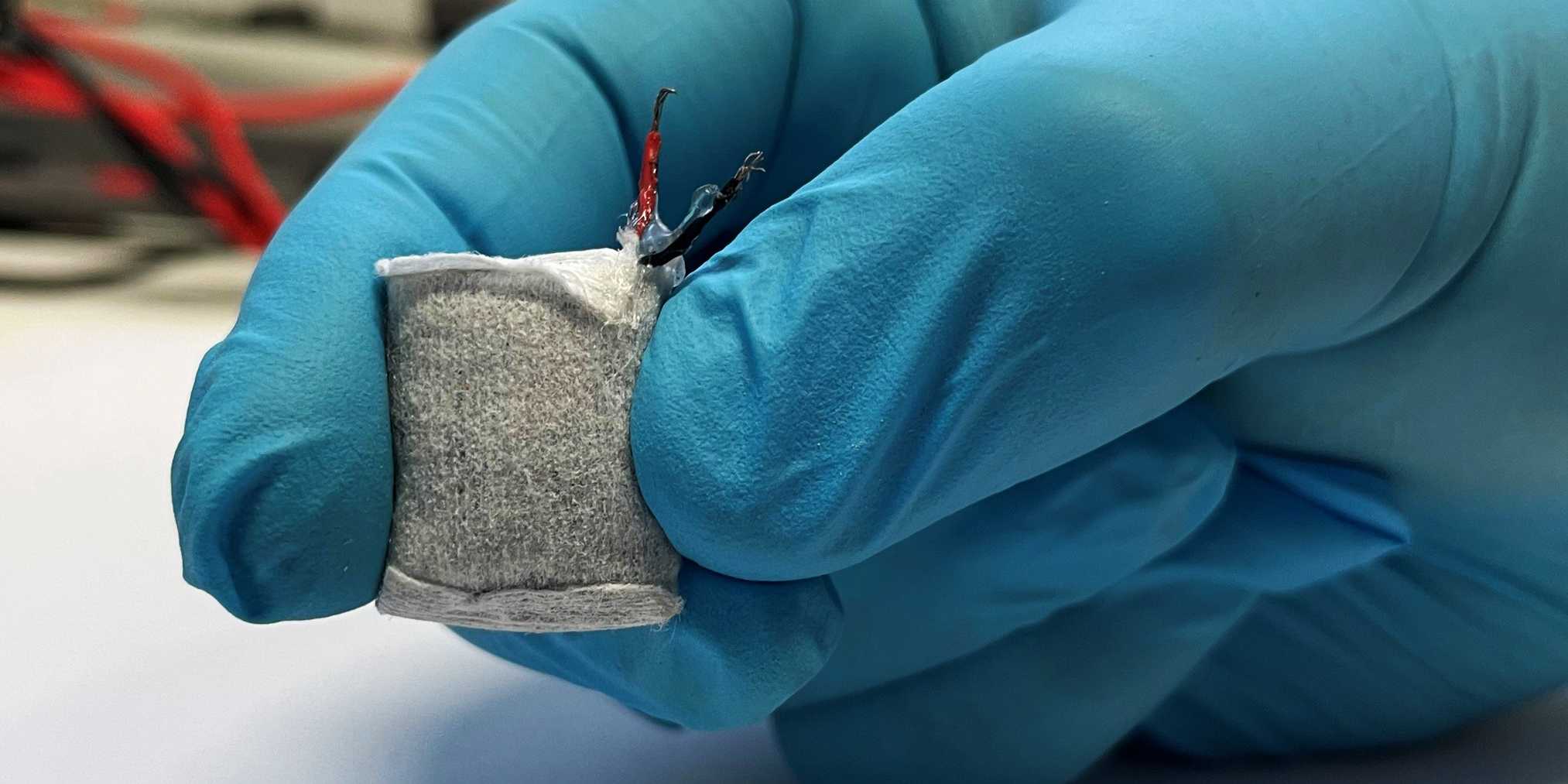

Now, MIT scientists have found a way to do just that with a newly developed treatment for surfaces involved in heating and evaporating water- the heat transfer coefficient (HTC) and the critical heat flux (CHF).

This is a great development since there is a trade-off between the two parameters – as one improves, the other gets worse. Both the parameters are important but enhancing both the parameters is a tricky business because of this trade-off.

The research team found a way of enhancing both after years of investigation

Bioinformatics scientist Youngsup Song from the Lawrence Berkeley National Laboratory in California says, “If we have lots of bubbles on the boiling surface, that means boiling is very efficient, but if we have too many bubbles on the surface, they can coalesce together, which can form a vapor film over the boiling surface.”

The vapor film introduces resistance to the heat transfer from the hot surface to the water, lowering the heat transfer efficiency and the CHF value.

So how did the researchers find the efficient and quicker boiling process?

They added a series of microscale cavities, or dents, to a surface to control the way bubbles form on that surface. This kept the bubbles effectively pinned to the locations of the cavities and prevented them from spreading out into a heat-resisting film. These microcavities were then positioned at the ideal length to optimize the entire process.