Forget layers. That’s the message from Manifest Technologies, which just debuted the world’s first Parallax Volumetric Additive Manufacturing (P-VAM) evaluation kit at RAPID 2025. And yes, it’s a big shift for the 3D-printing industry.

Born from the University of Colorado’s McLeod Lab and previously known as Vitro3D, Manifest is now taking a bold leap toward commercializing its radical new approach to 3D printing. One that doesn’t print layer by layer or rely on support structures. Instead, it builds entire solid objects — in seconds — with nothing but precisely controlled beams of light.

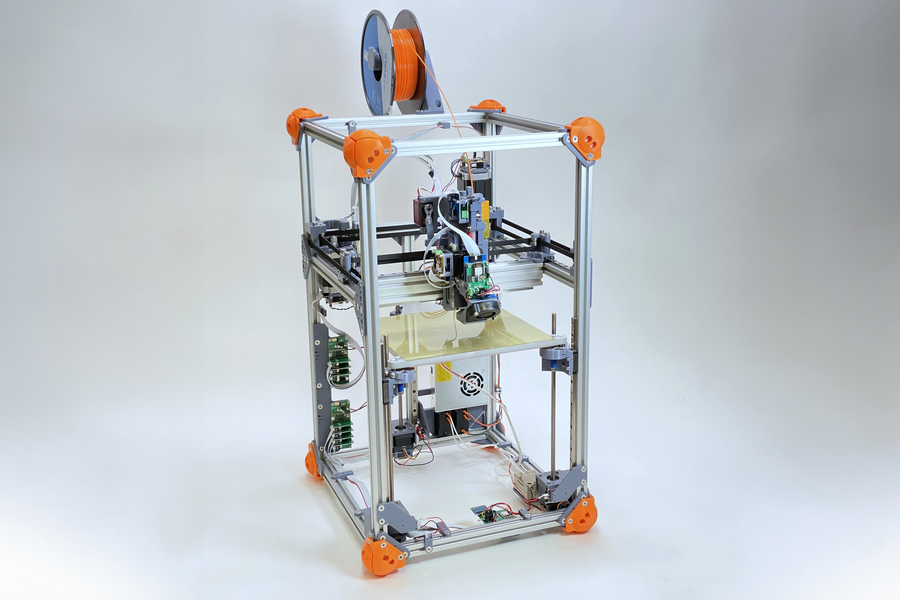

The kit offers engineers, R&D teams, and early partners a front-row seat to test and iterate with P-VAM firsthand. It’s not just a new machine. It’s a new category of additive manufacturing.

Unlike traditional 3D printers that work by slowly building up a part from slices, Parallax VAM cures liquid resin in three dimensions simultaneously. Think less printing, more manifesting. The result? Fully solid parts, formed in real time, up to 100 times faster than current additive methods. All without layers, supports, or the typical wait.

It’s fast, but also flexible. With P-VAM, designers can embed components directly into parts, manipulate resolution across complex geometries, and scale horizontally without limits. It’s especially suited for custom parts that would normally be limited by printer bed size or orientation constraints.

Material compatibility is wide open, too. Manifest’s platform supports a broad range of transparent photopolymer resins, even those with higher viscosities, allowing engineers to dial in performance based on application, not equipment limitations.

And forget bulky print farms. P-VAM’s compact, modular design is meant to live on the production line, integrating into existing workflows without disruption. It’s not a printer anymore — it’s a process.

“We founded Manifest to fundamentally reimagine additive manufacturing — moving beyond layer-by-layer printing to instant, multidimensional formation of solid parts using precisely controlled beams of light,” said CEO and co-founder Camila Uzcategui. “At a time when the more mature additive technologies are beginning to stagnate, we view the debut of our P-VAM evaluation kit at RAPID as an invitation to forward-thinking partners to join us and manifest different.”

At RAPID 2025, visitors witnessed the process live, saw parts formed on-site, and talked with the Manifest team about becoming an early adopter.