When Suraj Rama was 14 years old, he saw an article in Popular Science magazine about a science fiction-like miniature robotic device that could be used by doctors to explore the human body, much like in the “Fantastic Voyage” movie. Little did he know that a few short years later he would be making this vision a reality in his senior project at Boston University.

Walking In The Footsteps Of Pioneers

Two years ago, the Boston University Department of Biomedical Engineering (BME), led by a pioneer in the field of synthetic biology, James Collins, received over $26 million in research funding or more than $700,000 per faculty member. That year, 545 students were enrolled in the BME program with 301 students graduating with a degree in this fledgling field. With so many students in the program, each individual path taken by graduating seniors involves wearing a variety of “hats” and trying them on for size. Today we look at the path of one of the graduating seniors, Suraj Rama, that led him through the program.

Early Ambitions

Rama came to BU’s College of Engineering from his home state of New Jersey. His initial ambition was to become a medical doctor and he began studying pre-med as a freshman. His first stint outside the classroom was shadowing doctors in a local Boston hospital. As is usually the case for those entering the medical profession, there is a crucial point at which they must come to terms with whether or not they feel fully engaged in the process of helping people heal. Grappling with issues such as terminal illness, the adequacy of medicine and medical technology to help cure patients and experiencing patients’ illnesses and death is not to be taken lightly.

Research Lab Experience a Turning Point

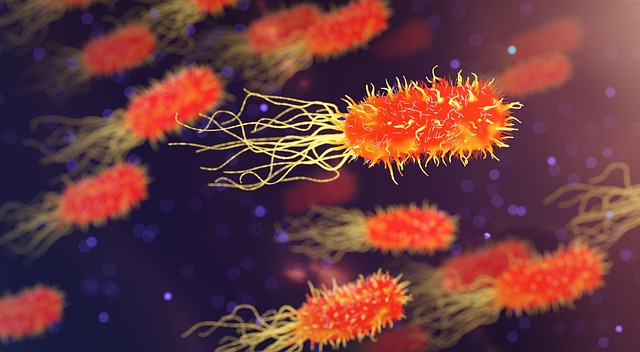

While Rama was witnessing the realities medical doctors face, he became interested in medical tools and devices and began working in a research lab at BU Medical Center. One of his first research projects was developing a new type of medicine to help those suffering from allergies. The team was studying parasitic infections experienced by people in Africa walking to lakes to fill water containers; parasites in the water would infect them, releasing anti-bodies in the form of proteins, which depress the immune system, limiting the reaction of white blood cells to the invader. The idea was to leverage this phenomenon and use it as a therapeutic treatment to limit the effects of allergies suffered by millions worldwide.

Today, the work done by Rama and the team he worked with has led to the development of new drug therapies for allergies which will soon hit the market. With no natural way of curing allergies to date, this new approach using naturally occurring substances as opposed to synthetic chemicals and “symptom suppressors” is a breakthrough. Another significant advancement in this area is the use of polymer shells in toothpaste and new inhalers which make ingesting new treatments less disruptive to a patient’s daily routine.

For Rama, this was a major turning point as he became increasingly aware of and interested in how the testing, research and development of new medicines and technologies can significantly impact the lives of patients. With this new focus, Rama found his motivations and ambitions aligned and moved forward to the next stage of his development.

Fixing Medical Equipment Opens a New Path

Rama’s next step was to become an equipment tech volunteer at a local Boston hospital in an in-house medical device department. His job involved re-certifying medical devices. This led to an internship at Medtronic and the experience of working for a manufacturer and seeing how a research and development project is transitioned to manufacturing.

During this time, Rama was involved in discrete manufacturing or the creation of one-off designs that would be tested to see if they could be efficiently and cost effectively manufactured. He supported the R&D team, made fixtures and devices, did stress analysis using Solid Works, tested catheters for yield strength using an Angstrom machine and helped create an inventory management system for the advanced discrete manufacturing laboratory using a barcode system and MS SQL.

His major project at Medtronic was the creation of CoreValve, a transcatheter aortic valve replacement delivery system. His team collaborated with Medtronic’s R&D group to develop a process to manufacture CoreValve while meeting stringent performance criteria.

Development of a Wireless Powered Endoscopy Capsule Robot

Rama’s Senior Project at BU, completed with colleagues Jason Pui and Ben Szewczyk and technical advisor Seung-Schik Yoo, Phd., was the development of a “reconfigurable endoscopic capsule minibot” using a modular assembly.

According to Rama, the Israeli company Given Imaging, recently purchased by Covidien, had developed the first commercial capsule endoscope but with limitations. While Given Imaging pioneered the use of swallowable “pill like” cameras, they had limited functionality such as being unable to take a biopsy, stop at a certain location or reposition themselves to get a closer look at pathological areas. Rama and his team conceived of a robotic pill that would be able to explore and have increased functionality.

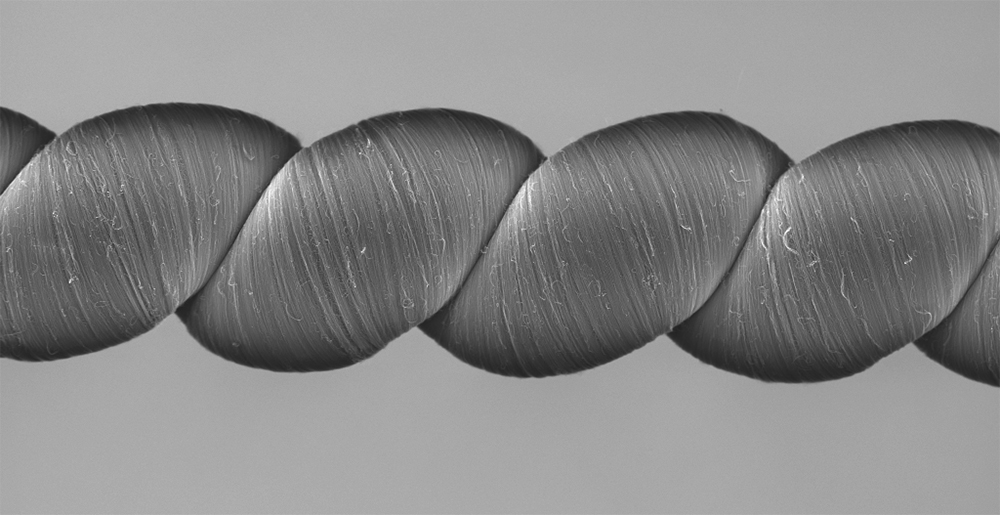

The team designed a series of wirelessly powered modular robots (see video) with different functionality: biopsy, camera, etc. The robots would be swallowed individually and assemble into a larger more complex robot inside the stomach, a process which has been described as similar to spaceship docking.

The Path Forward

Rama recently completed several projects at Manta Product Development, a design firm located in Cambridge, Massachusetts and aims to work in the field of product development of medical devices.

For more or to contact Rama visit his LinkedIn page.

Related articles on IndustryTap: