Some time back, researchers from Rice University discovered the way to manufacture graphene with a laser. However due to the flimsy nature of this flaky foam, it lacked real-life functionality.

But now, the research team led by Rice chemist James Tour, has created composites with variety of applications, by infusing laser-induced graphene (LIG) with plastic, rubber, cement, wax, or other materials.

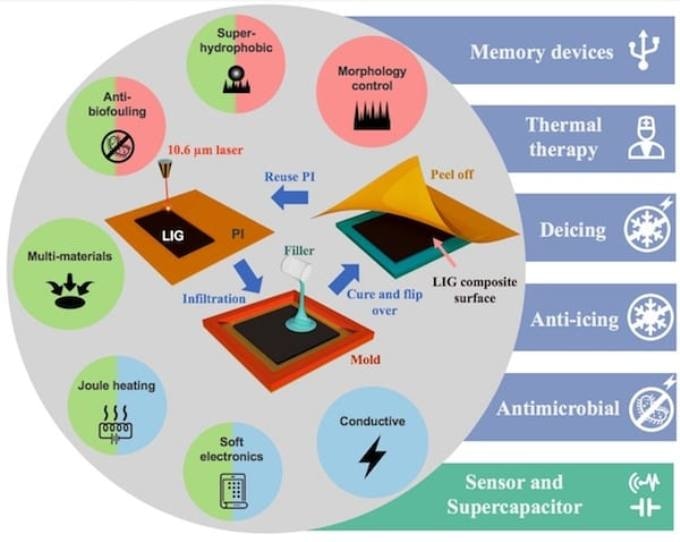

For making the composites, researchers simply poured or hot-pressed a thin layer of the second material over LIG attached to polyimide. After a while, when the liquid hardened, they pulled the polyimide for reuse, leaving connected graphene flakes behind.

“You just pour it in, and now you transfer all the beautiful aspects of LIG into a material that’s highly robust,” Tour said.

These composites could be used in wearable electronics, anti-icing, antimicrobial applications, sensors and water treatment

Tour explained that the soft composites can be used for active electronics in flexible clothing, whereas harder ones can be used to make excellent super-hydrophobic (water-avoiding) materials. It can also be used to make toughened versions of the material suitable for antibacterial applications.