Industrial technology seems to get more and more mind-blowing every single day.

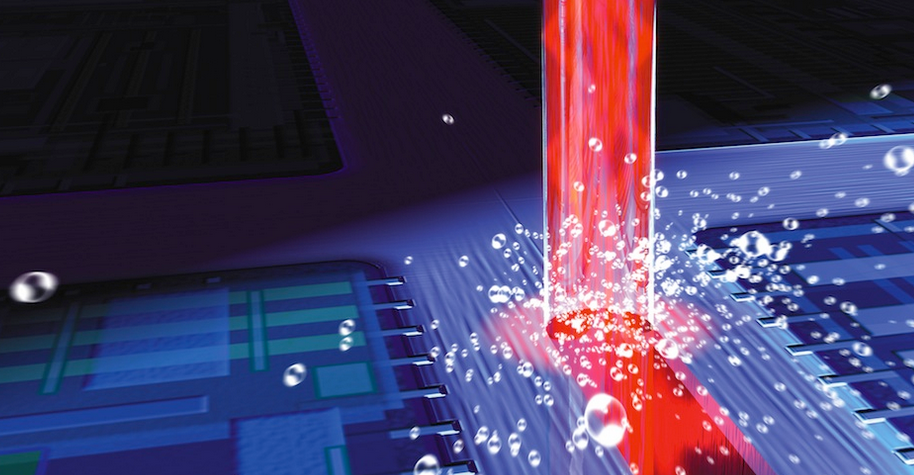

For example, the Laser MicroJet is capable of blasting cooling holes in extremely strong turbine blades by shooting a laser beam inside a hair-thin jet of water. It sounds insane, but here is how it works according to GE:

Putting holes in turbines that handle titanic pressure may sound crazy. But these holes are necessary for cooling. Above is an image of the powerful tool used for such a daunting task. The Laser MicroJet drills tiny holes in a turbine blade by firing a laser beam inside a hair-thin jet of water, which guides the laser to the blade’s surface.

In order to eliminate the possibility of contamination or heat damage on the cut side, innovative laser systems like these are used because of their overall precision and reliability.