Conveyor belts are highly efficient for transporting materials across long distances, thus able to significantly cut emissions. Depending on the design, they can reach between 85% to 95% efficiency, which simply can’t be reached by any other land transport. Currently, the world’s largest conveyor belt is located in the Western Sahara, stretching approximately 61 miles (98 km) to transport phosphate rock from mines to the coast for export.

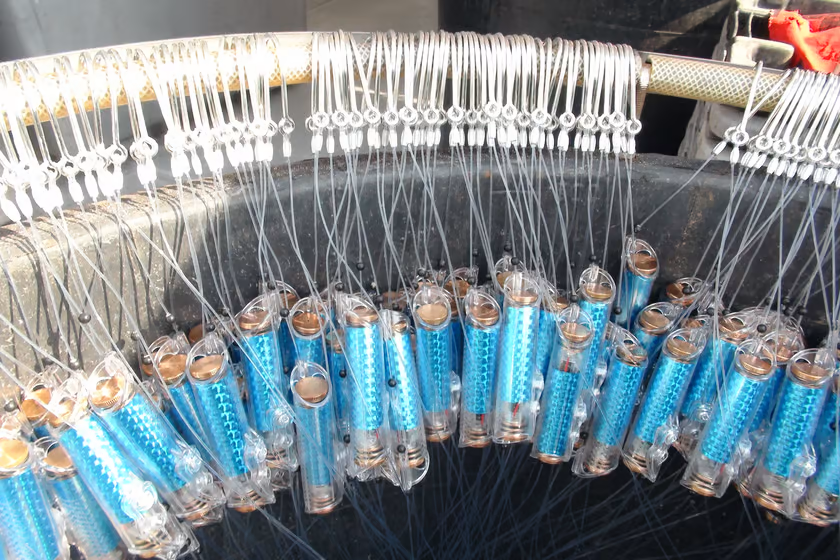

However, Japan’s Ministry of Land, Infrastructure, Transport and Tourism (MLIT) wants to build a conveyor belt that would trump the one in Western Sahara. Spanning from Tokyo to Osaka, the automated cargo transport corridor will be around 310-miles (500-km) long and positioned in the middle of the country’s existing highways. Engineers imagine a three-lane corridor that can transport larger wheeled boxes, measuring 43.3 inches (110 cm) wide and long, and 71 inches (180 cm) high. The conveyor belt will work 24 hours a day, too. By doing this, Japan will limit its reliance on drivers, which are an endangered species in the country.

Still, the automation part goes even further, with the system relying on automated forklifts, which would transport the packages from airports and railways to the conveyor belt. Nonetheless, human drivers will still oversee last-mile deliveries, like to businesses or people’s homes. In the future, though, driverless vehicles will be used to limit human involvement, as annual fatalities from delivery vehicle crashes reach 1,000 in Japan.

Despite concerns of crime related to the conveyor belt, Japan needs this solution to start working as soon as possible. At this rate, the country’s overall transport capacity will plunge by 34% by the end of this decade, because 91% of it is supported by trucks. Moreover, the pandemic has significantly accelerated demand for online shopping deliveries, further necessitating the need for an automated cargo transport corridor.

Japan plans a trial run of the world’s largest conveyor belt in late 2027 or early 2028, with a fully operational corridor ready circa 2035.