Confronting Challenges in Wind Energy

In the realm of wind energy, damp and cold weather pose significant challenges for wind turbines. Ice on rotor blades causes rotational imbalances, leading to heightened levels of wear and tear. In instances where this occurs, turbines necessitate shutdowns that can extend over several days, resulting in substantial losses for operators as electricity production temporarily halts.

While anti-icing heating systems can be integrated into the blades, they may be costly for some wind farm operators.

Drones Revolutionizing Ice Prevention

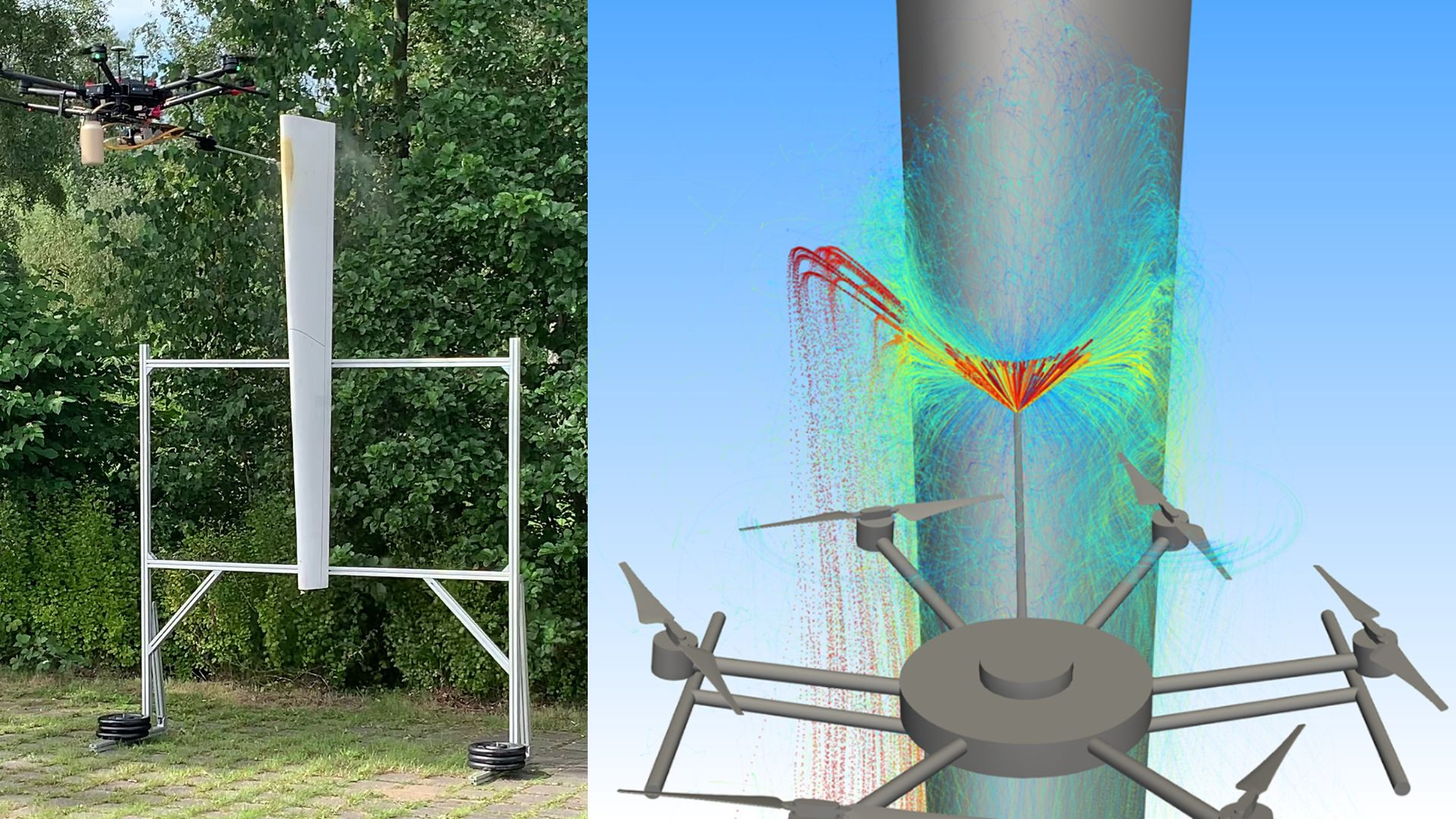

Scientists from two branches of Germany’s Fraunhofer research group are exploring an economical solution. They have initiated the “TURBO – Temporary coating by means of drones” project with the goal of investigating drones’ potential for applying a temporary coating.

The present system utilizes a hexacopter drone with a small pump. The pump delivers a urea/wax anti-icing fluid from an onboard tank into a slender lance. This lance features a nozzle just 0.3 mm wide, from which the fluid is sprayed at high pressure. The result is the production of tiny droplets with a diameter of 100 micrometers.

This setup enables the drone to effectively apply coatings of atomized droplets onto the ice-prone edges of wind turbine blades. Remarkably, it achieves this even at wind speeds of up to 35 km/h (22 mph). Once solidified, these coatings prevent ice formation for several weeks before losing adhesion. Subsequently, a fresh coating can be applied.

Image by Fraunhofer IPA

Beyond Wind Turbines: The Versatility of Drone Solutions

Encouraged by their success, the researchers are collaborating with industry partners to enhance as well as prepare the technique for mass production. They envision applications beyond wind turbines, foreseeing its utility in safeguarding overhead lines in rail transport and refurbishing hard-to-reach sections of buildings.