Fluid handling technologies are undergoing rapid advancements, bringing transformative changes to manufacturing processes. These innovations are essential for improving efficiency, reducing costs, and maintaining product quality. Understanding these technologies can help you stay competitive in a dynamic industry landscape.

Manufacturing processes rely heavily on fluid handling systems to transport, measure, and control liquids and gases. As with many different sectors, the advent of new technologies is making these systems become more efficient, reliable, and environmentally friendly. This article explores the latest advancements in fluid handling technologies and their impact on manufacturing industries.

Advancements in pump technology

Pumps play a crucial role in fluid handling systems by moving liquids through pipelines, tanks, and other equipment. Recent advancements in pump technology have significantly improved their efficiency and reliability. One notable innovation is the development of pumps like the Husky double diaphragm pumps, which offer superior performance and durability compared to traditional pumps. These pumps are particularly beneficial for handling abrasive or viscous fluids, ensuring smooth and uninterrupted operation.

Another important advancement is the integration of smart sensors and IoT capabilities into pump systems. These technologies enable real-time monitoring and control of pump performance, reducing downtime and maintenance costs. By leveraging data analytics, manufacturers can optimize their fluid handling processes, resulting in increased productivity and cost savings.

The emergence of magnetic drive pumps represents another significant breakthrough in pump technology. These pumps use powerful magnets to transmit torque from the motor to the impeller, eliminating the need for shaft seals. This design offers several advantages, including zero leakage, reduced maintenance requirements, and the ability to handle hazardous or corrosive fluids safely. Magnetic drive pumps are particularly valuable in industries such as chemical processing, pharmaceuticals, and semiconductor manufacturing, where fluid purity and containment are critical.

Revolutionizing valve technology

Valves are essential components in fluid handling systems, regulating the flow of liquids and gases. The latest innovations in valve technology focus on enhancing precision, reliability, and ease of maintenance. New materials such as advanced polymers and ceramics are being used to manufacture valves that offer superior resistance to corrosion and wear. This ensures longer service life and reduced maintenance requirements.

Additionally, smart valves equipped with sensors and actuators enable remote monitoring and control, allowing for real-time adjustments to flow rates and pressure levels. This level of automation helps prevent system failures and optimizes energy consumption.

Enhancing filtration systems

Filtration is a critical aspect of fluid handling, ensuring that contaminants are removed from liquids before they enter sensitive equipment or final products. Recent advancements in filtration technology have led to the development of more efficient and reliable filters. Innovations such as self-cleaning filters and high-capacity filtration media help maintain optimal flow rates while minimizing maintenance requirements.

Moreover, the integration of smart sensors into filtration systems enables continuous monitoring of filter performance. This allows for predictive maintenance, reducing the risk of unexpected downtime due to clogged or malfunctioning filters. By maintaining clean fluids throughout the manufacturing process, you can ensure higher product quality and consistency.

Sustainable practices in fluid handling

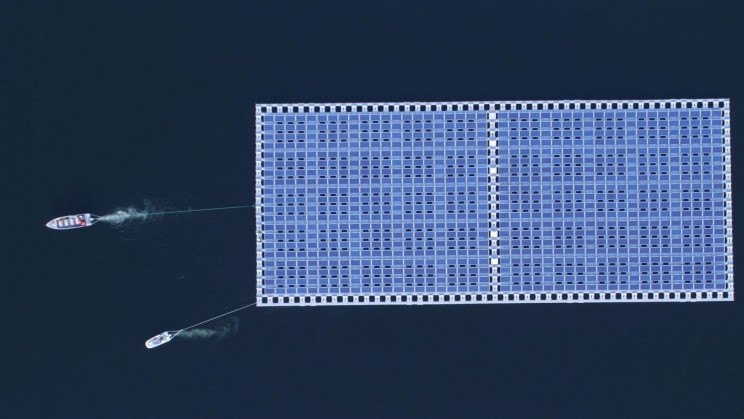

Sustainability is becoming increasingly important in the manufacturing industry as companies strive to reduce their environmental impact. Innovative fluid handling technologies play a vital role in promoting sustainable practices by improving energy efficiency and reducing waste. For example, energy-efficient pumps and valves help minimize power consumption while maintaining optimal performance.

In addition to energy savings, advanced fluid handling systems enable the recycling and reuse of process fluids. This not only reduces the consumption of raw materials but also minimizes wastewater generation. By adopting these sustainable practices, manufacturers can lower their operational costs while contributing to environmental conservation. The importance of contributing to sustainable practices cannot be overstated. In addition to protecting the limited natural resources that we use in some capacity, being seen as an eco-leader in sustainable practices is becoming increasingly important for many different stakeholder groups across multiple industries.