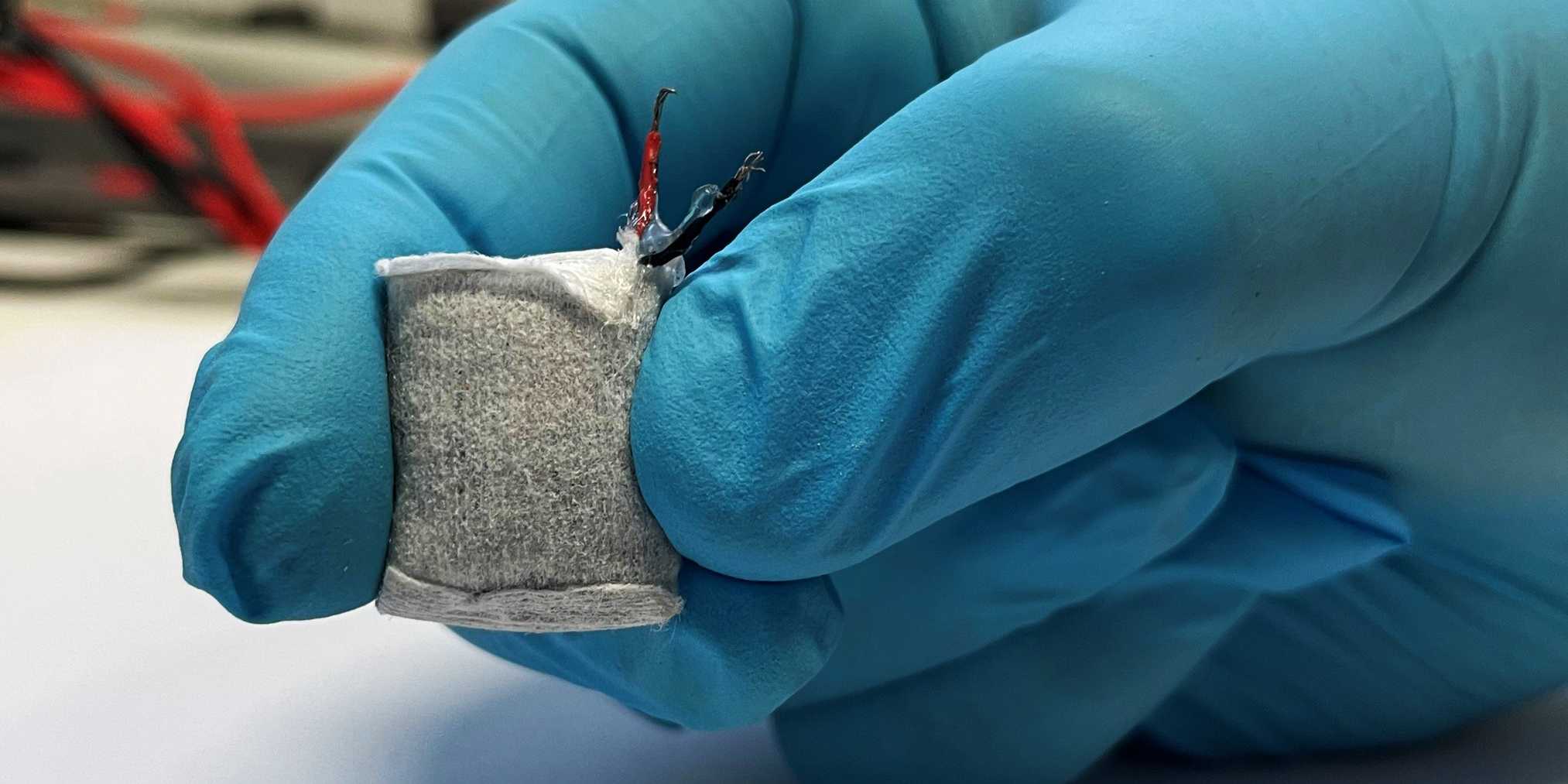

HPMB® fiber-reinforced composite bearings are the latest innovation solution from GGB Bearing Technology, manufactured by an intricate filament winding process.

Comprised of a fiberglass backing and self-lubricating liner material, HPMB® bearings are designed for high strength and impact resistance, corrosion resistance, and negligible water absorption.

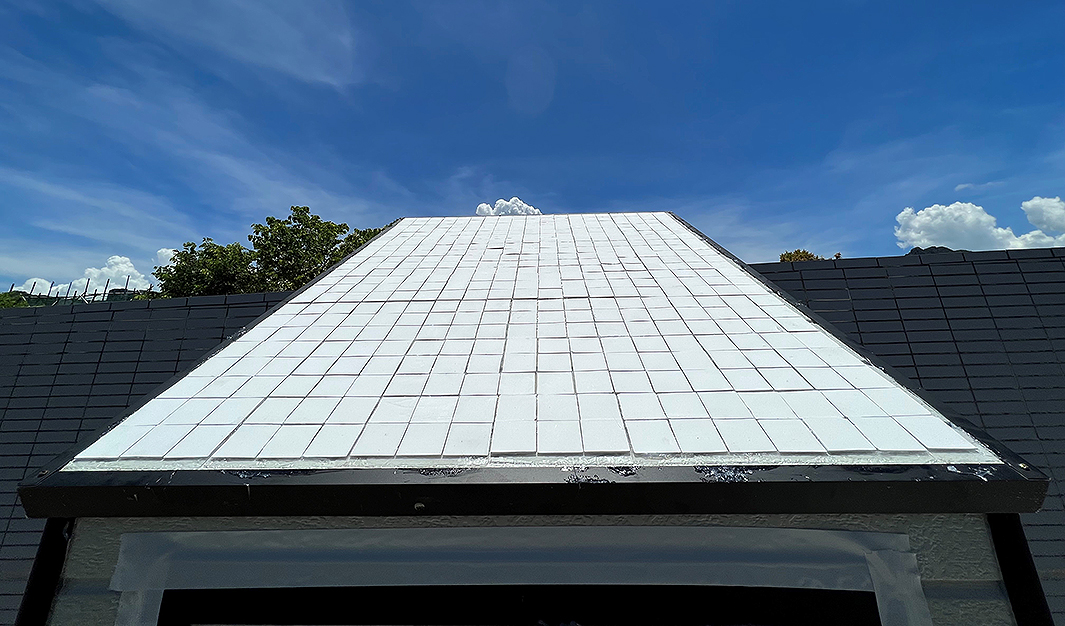

The HPMB® bearing’s class-leading tribological properties and outstanding dimensional control (inner diameter tolerance IT7 attainable), make it perfect for hydropower water turbine and industrial applications.

One of the main differences between HPMB® and other bearing materials is that it features a fully machinable liner enabling a precise fit, unattainable by other technologies.

Yuri Klepach, Fiber Reinforced Composite Product Manager at GGB says, “Many customers that we witness in the field note they already buy GGB bearings but sometimes have a need to touch up the size after installation. They ask, can we do it? So strictly for that purpose we have developed the [liner material] so the customer can still install it and if needed, machine the inner diameter on spot.”

GGB

Its self-lubricating properties make it ideal for aqueous and dry environments.

“HPMB® material has been tested by the US Army Corps of Engineers for the water turbine protocol and it has been approved for usage in a water turbine”, adds Klepach.

GGB

Perhaps the most intriguing feature is the bearings’ extremely low coefficient of friction (0.068), thanks to its fiber reinforced composite construction process, enabling turbine designers to greatly reduce costs. In addition, it allows the bearings to remain dimensionally stable when used under water – meaning it does not swell and absorbs little water.

The benefit of bearings requiring lower friction in the operating mechanism of a water turbine is that it gives the designer the ability to use smaller servomotors, reducing the cost and size of the overall turbine, according to Klepach.

The propensity of HPMB® bearings to withstand heavy loads, slow speeds, and provide precise tolerances allow them to replace traditional greased bronze bearings for industrial applications.

For ultimate precision in your unique industrial application, choose GGB’s HPMB® bearings.