While it is possible to recycle carbon fiber to some extent, currently it is being discarded after it gets damaged. That, however, may change soon. Recently a study claimed that heat application could make it possible to fix or reuse a new type of material.

At present, carbon fiber reinforced polymers (or CFRPs for short) are being used for making carbon fiber products. CFRPs, in turn, come in two flavors — thermoplastic and thermoset.

Both of them have certain limitations that make them difficult to fix or reuse. For example, thermosets get hardened once cured because of a polymer called epoxy. While this makes thermosets extremely strong, it makes reworking them extremely hard.

On the other hand, thermoplastics contain a softer polymer, which makes it possible to easily melt them. However, the downside is that thermoplastics are not as stiff or strong as thermosets.

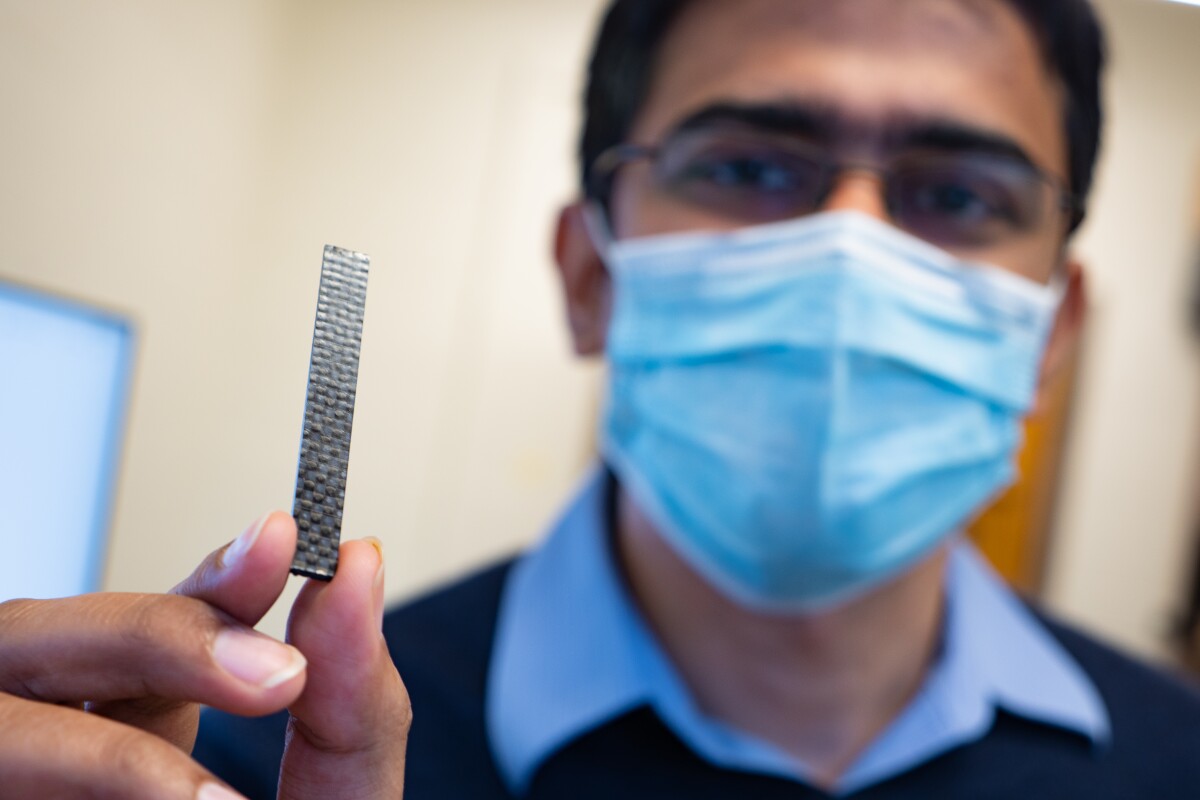

Because of the inherent limitations in these materials, a University of Washington team led by Asst. Prof. Aniruddh Vashisth looked at a group of different materials, known as carbon fiber reinforced vitrimers (or vCFRPs for short). The best thing about the vCFRPs is that they combine the best properties of thermoplastics and thermosets.

The vCRFPs contain strong chemical links, and as such are both stiff and strong. However, unlike thermosets, they are easy to rework with and regain their strength once they cool down after having been melted. This, in turn, makes it possible to repair degraded or damaged vCFRPs more than once.