Introduction of Innovative Technology

Researchers at the University of Delaware in Newark have developed a new technology with the potential to revolutionize textile recycling and curb the ever-growing problem of fast fashion waste. This innovative method addresses the longstanding challenge of recycling clothes made from blended fabrics.

Overcoming Traditional Recycling Hurdles

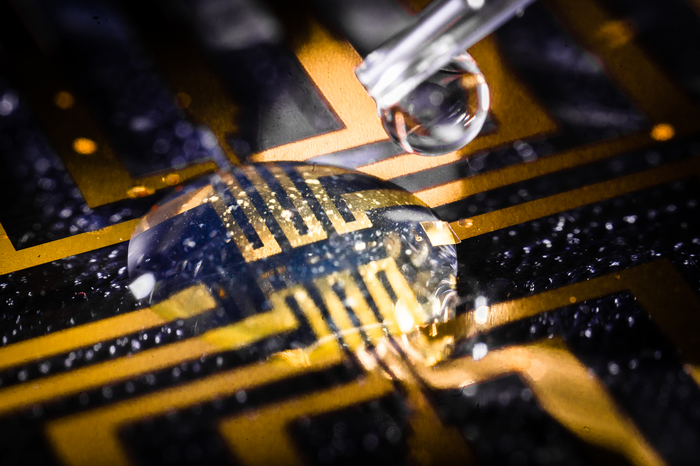

Traditionally, separating different fibers like polyester, nylon, cotton, and spandex in mixed textiles has been a major hurdle for recycling plants. The University of Delaware’s solution lies in a chemical process called microwave-assisted glycolysis. This method utilizes zinc oxide as a catalyst, accelerating the breakdown of polyester and spandex into their basic building blocks. The beauty of this process is its ability to target specific fibers while leaving cotton and nylon relatively unharmed.

Promise for Large-Scale Implementation

This innovation holds immense promise for large-scale implementation. By efficiently separating and recycling various fibers, reliance on virgin resources like cotton and petroleum for synthetic fibers can be significantly reduced. Not only does this lead to a more sustainable fashion industry, but it also paves the way for a more circular economy within the textile sector.

Impact on the Fast Fashion Industry

The fast fashion industry, notorious for its contribution to textile waste, could be significantly impacted by this groundbreaking technology. The ability to recycle mixed-fiber clothing effectively offers a viable solution. It can divert mountains of garments from landfills and create new clothing from previously discarded materials.

A Step Towards a Sustainable Future

The University of Delaware’s research marks a significant step towards a more sustainable future for the fashion industry. This new recycling technology has the potential to reshape how we manage textile waste as well as usher in a new era of responsible clothing production and consumption.