The first waves of “globalization” the world remembers most clearly were increases in trade flows that occurred beginning in 1850 and ending with World War II. During this time, countries directly sought to increase wealth through colonial rule. Of course, this type of activity had gone on for ages but it was different in that the industrial revolution was in full swing and humans began competing over resources to feed their nascent industries.

The oft used term “globalization”, then, is not just a a buzzword or an abstract concept, though its meaning has changed. Today it means the internationalization of industries but this time it is being driven by a new technological revolutions in computers, biotechnology, materials science, etc. Notable over the last decade is that the pace of change has been quickening as more and more manufacturers are completely transforming the way they operate.

Trends in the aerospace business are a perfect illustration of what is happening: internationalization of supply chains, widespread outsourcing of responsibilities for design and production, and companies are now using “shared resources” to get things done.

The Dawn of Shared Service Model: Improving Inputs, Spreading Risk

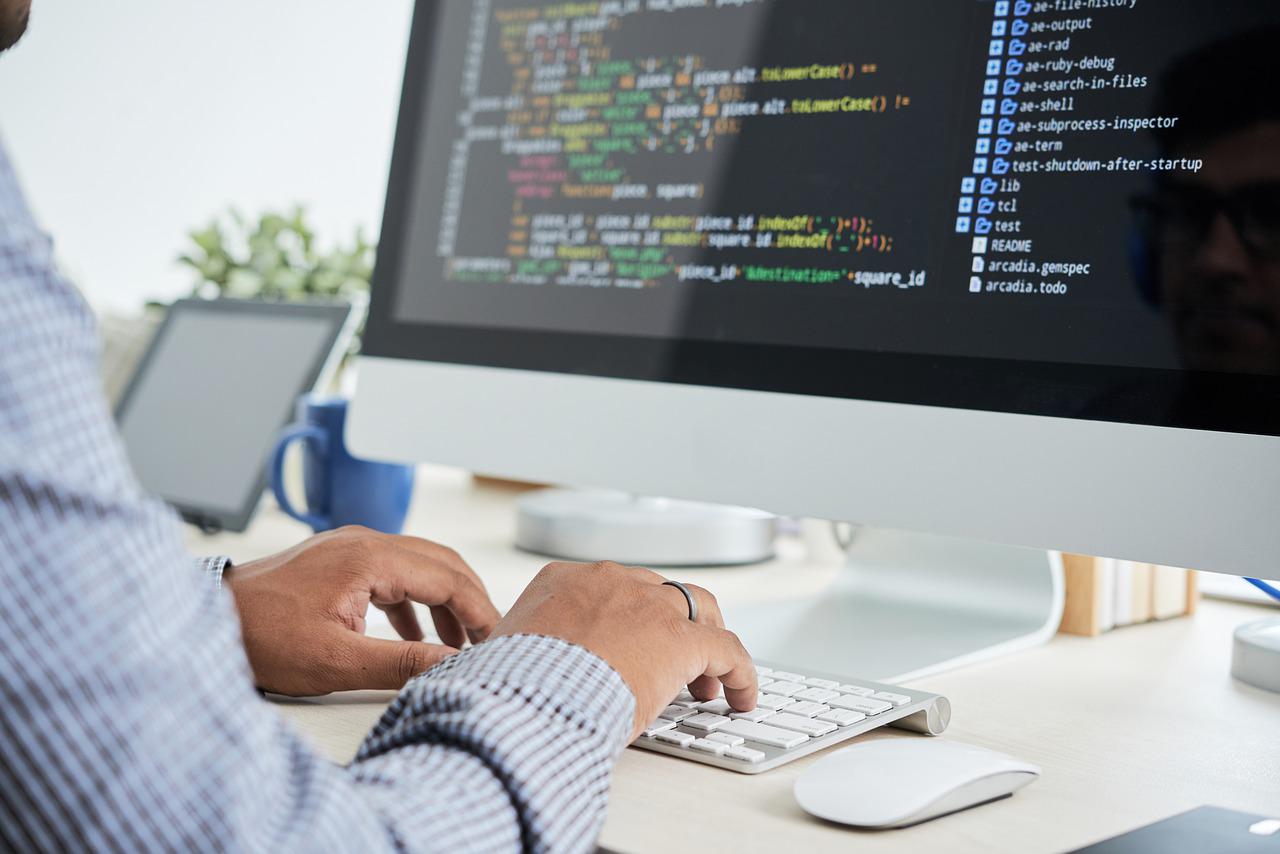

Leading companies in the aerospace industry are increasingly using “Business Process Outsourcing” (BPO) which is leading to “shared services” and reduced costs. Companies in the United States and Europe regularly rely on Indian software companies for development of design and systems and are able to thin overhead and the ranks of management, operating leaner, more efficient operations.

The huge costs of running global operations, the fickleness of government regulations from country to country and added risks from natural disasters and political instability, make commitments to 100% ownership by each company of all the operations they need is unprofitable.

Due in large part to the internet, the fuel on which the world runs, digital information, can now be obtained from any corner of the globe, from the most skilled group available, with the flip of a switch. Gone are the days where everything is done in-house. Boeing, for example, used to employ 100,000 designers and engineers to manufacture entire planes entirely in-house. Today, Boeing handles final assembly only, contracting out everything else.

Related articles on IndustryTap:

- Fossil Fuel Costs Driving New Era Of Aerospace Computational Engineering

- Kuka Aerospace To Open 29,000 Square Foot Facility Next To Boeing In Everett

- The Dinosaur Eats Dinosaur World of Global Aerospace & Defense

Related articles on IndustryTap: