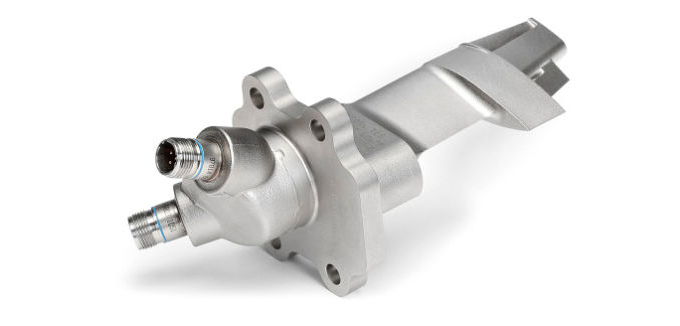

The first 3D printed part cleared for use on a commercial jet engine is…

GE’s T25, which was recently officially approved by the U.S. Federal Aviation Administration!

The new part should see some action relatively soon because General Electric is currently working with Boeing to retrofit over 400 of its GE90-94B engines — used on the modern 777.

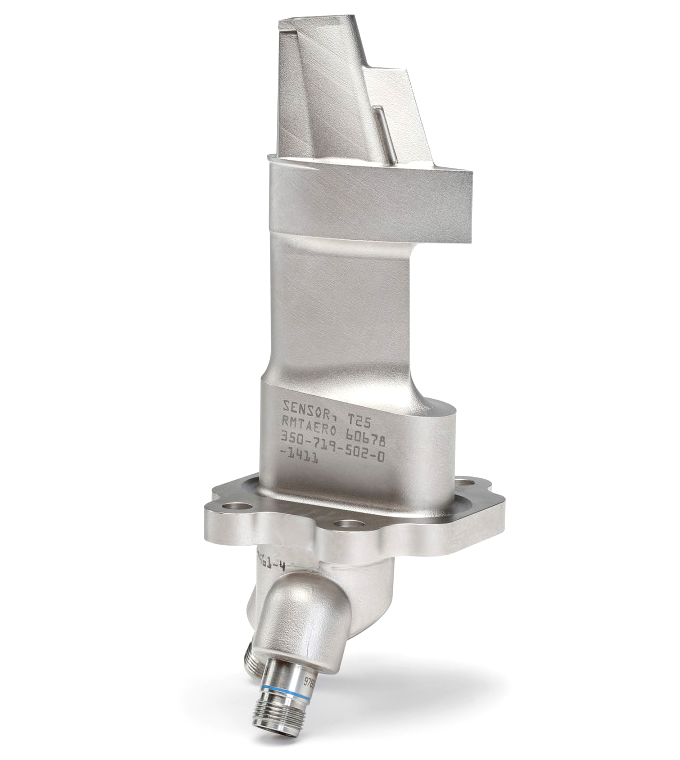

It is worth noting that GE’s T25, which will be responsible for protecting compressor inlet temperature sensors from icing, was not constructed by one of the 3D-printers you can buy at Home Depot.

In fact, it is a fist-sized silver metal housing created using a 3D printer using additive manufacturing techniques, in addition to an extremely accurate laser.

The laser is pointed at layer after layer of cobalt-chrome powder in order to gradually build up the part over time.

In the end, the precise process leads to a part just as strong and durable as traditional manufacturing techniques, the only difference being it was made faster is is probably more complex, thanks to 3D-printing.

And the best part?

Minimal material is wasted during production. That’s tough to beat!

Via: Despatch