Electronic-based products represent the fastest-growing items in the waste stream worldwide. Moreover, present electronics fabrication technology involves hazardous chemicals and toxic gases.

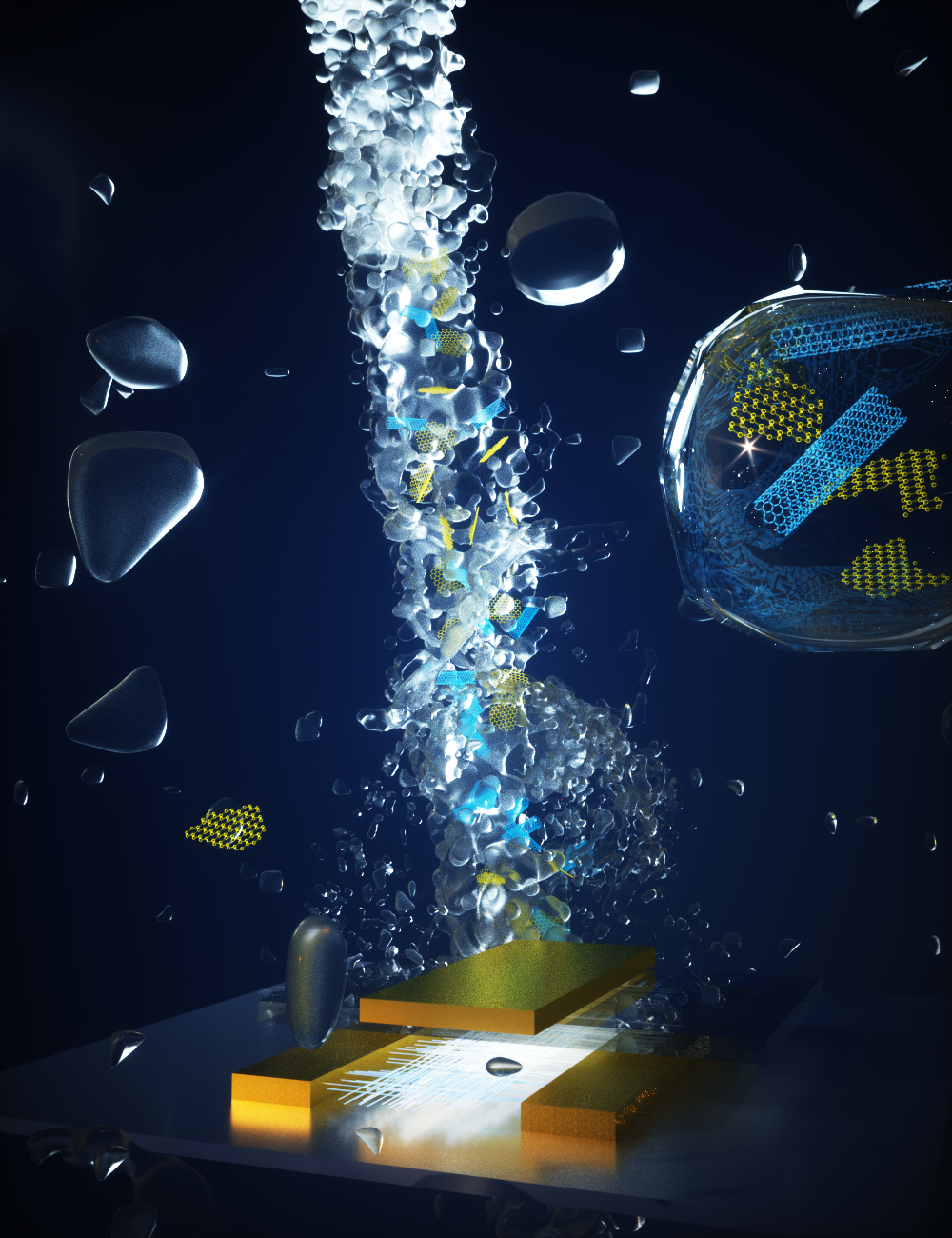

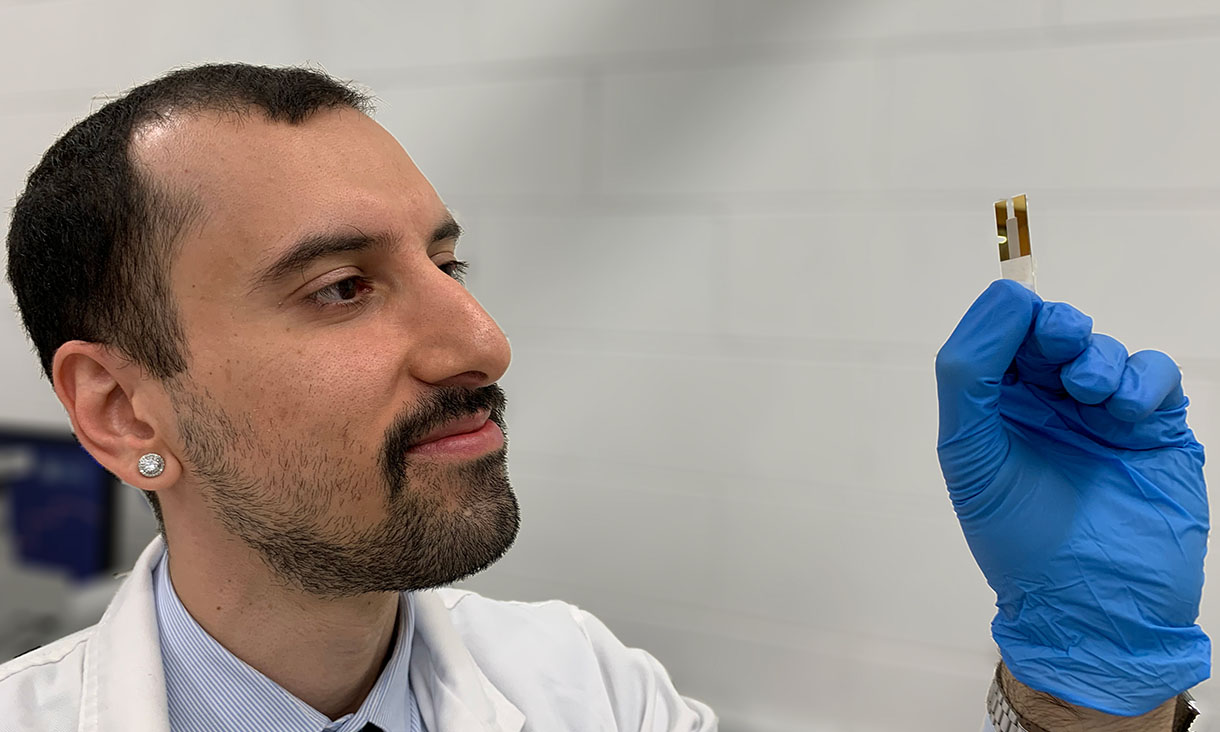

For reducing the environmental footprint and human health risks, Duke University researchers have produced the world’s first fully recyclable printed electronics that use water in place of toxic chemicals in the fabrication process.

In the electronics industry, it is very challenging to successfully place several layers of components on top of each other

Besides, in the case of printed electronics, this task is more complicated.

“If you’re making a peanut butter and jelly sandwich, one layer on either slice of bread is easy,” Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke, said in a statement.

“But if you put the jelly down first and then try to spread peanut butter on top of it, forget it, the jelly won’t stay put and will intermix with the peanut butter. Putting layers on top of each other is not as easy as putting them down on their own — but that’s what you have to do if you want to build electronic devices with printing.”

For developing a water-based ink in which the carbon nanotubes don’t clump together, researchers added a surfactant similar to detergent.

But the resulting ink does not create a layer of carbon nanotubes dense enough for a high current of electrons to travel across

“You want the carbon nanotubes to look like al dente spaghetti strewn down on a flat surface,” said Franklin.

“But with water-based ink, they look more like they’ve been taken one by one and tossed on a wall to check for doneness. If we were using chemicals, we could just print multiple passes again and again until there were enough nanotubes. But water doesn’t work that way. We could do it 100 times and there’d still be the same density as the first time,”

Franklin and his team then developed a cyclical process. In this process. the device is rinsed with water, dried in relatively low heat, and printed on again.

“When the amount of surfactant used in the ink is also tuned down, the researchers show that their inks and processes can create fully functional, fully recyclable, fully water-based transistors,” the release said.