From the early days of industrial development, compressors have had a huge impact on a myriad of engineering applications, influencing how many industries operate and how they have evolved. This technology plays a key role in a range of processes, from simple air conditioning systems in your home to complex machinery in manufacturing plants.

The development of compressors has mirrored advancements in engineering, showing a history of innovation and adaptation. With each technological leap, compressors have become more efficient, reliable, and integral to modern industry. This evolution reflects the constant pursuit of improving and adapting technology to meet the changing demands and capabilities of the times. As we delve into this history, you will gain a deeper appreciation for how essential these technologies are in shaping the world around you

The Origins of Compressor Technology

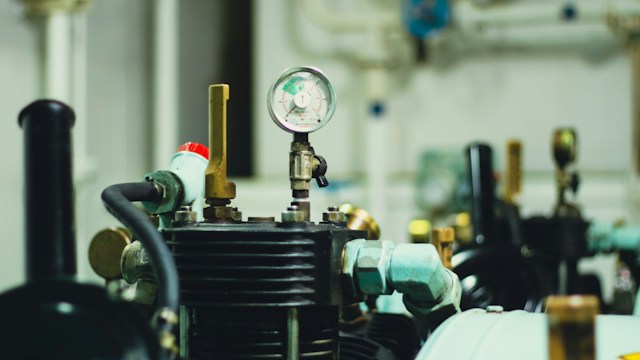

Tracing the origins of compressor technology reveals a fascinating aspect of our industrial heritage. The basic concept of air compression dates back to the bellows used by ancient blacksmiths, a simple yet effective tool for stoking fires. The Industrial Revolution brought significant advancements, transforming compressors into essential tools for a variety of applications.

These early machines were primarily steam-powered, playing a crucial role in the burgeoning industrialization of civilization. The evolution of compressors mirrors the broader trends in engineering and manufacturing, adapting to the demands of growing industries. From powering pneumatic tools to enabling the operation of large-scale machinery, the historical development of compressors demonstrates their importance in shaping modern technology and industries.

Enhancing Efficiency and Performance

Recent years have witnessed groundbreaking innovations in compressor design, directly impacting your world. Engineers have focused on enhancing efficiency and performance, leading to compressors that consume less energy while delivering more power. This progress is not just about improving existing designs, it reimagines what compressors can do. Innovative materials and cutting-edge manufacturing techniques have resulted in lighter, more durable, and more efficient models.

These advancements are crucial in industries where precision and reliability are paramount. They also play a significant role in reducing operational costs and environmental impact. While you go through your day-to-day life, these improvements in compressor technology are working silently in the background, ensuring smoother and more efficient operations across numerous applications.

Eco-Friendly Compressor Technologies

Recent advancements in compressor technology are reshaping our approach to environmental sustainability. These state-of-the-art compressors are engineered for maximum efficiency, dramatically lowering energy usage and reducing industrial carbon emissions. The shift towards eco-friendly technology involves innovative materials and manufacturing methods that extend the lifespan of compressors while minimizing environmental impact. Modern oil-lubricated air compressors use less energy, create less noise, and are more reliable. This range from Champion is designed to be quiet, cost-effective, and have a reduced impact on the environment.

This progress represents a pivotal step towards harmonizing industrial efficiency with ecological responsibility, offering tangible benefits not only for the environment but also for industry economics. Embracing these sustainable technologies is crucial for fostering a healthier planet and a more cost-effective industrial landscape.

Challenges and Solutions in Compressor Deployment

Deploying advanced compressor technology comes with its unique set of challenges, impacting industries and your experiences with them. These challenges range from integrating new technologies into existing systems to ensuring operational efficiency and cost-effectiveness. Overcoming these hurdles often requires innovative thinking and a willingness to adapt to new methods.

Solutions include training personnel in the latest compressor technology and implementing best practices for maintenance and operation. By addressing these challenges head-on, industries not only improve their efficiency but also contribute to a more sustainable and economically viable operation. Your understanding of these complexities helps in appreciating the value and effort behind the seamless functioning of everyday technologies.

Predicting the Next Advancements

Looking ahead, the future of compressor technology holds exciting prospects that will influence your world. Innovations are likely to focus on enhancing energy efficiency and further reducing environmental impact. Anticipate a surge in the use of smart technologies, integrating IoT and AI for proactive maintenance and optimized performance. These advancements will not only improve the operational lifespan of compressors but also enhance user experience through real-time monitoring and adjustments.

Expect also a push towards more compact and noise-reduced designs, making compressors more adaptable to a variety of settings. Advancements are likely to yield more compact and quieter compressor designs, making them suitable for a broader range of applications. This forward-thinking approach in compressor technology promises not just incremental improvements but significant leaps, contributing to both the efficiency and sustainability of modern industries.

Compressors are more than behind-the-scenes players in modern engineering. Their integration into various industries has become indispensable, profoundly affecting your everyday experiences. The ongoing evolution of compressors, marked by innovative designs and sustainable practices, underscores their pivotal role in advancing technology and industry.

Understanding their importance is crucial, as it reflects a broader appreciation for the technologies that quietly power our world. Embracing these advancements ensures that compressors will continue to be integral, efficient, and environmentally conscious components in the engineering landscape.