FACC AG is an Austrian composites developer and manufacturer who provides advanced aeronautical solutions. From lightweight wings, tails, and fuselage parts, to engine parts, sidewall panels, ceiling panels, and luggage racks, FACC makes everything out of strong, light, and durable composite materials that companies like Boeing, Airbus, Embraer, and Bombardier love to use in their aircraft. In fact, composites are where all the focus in aviation is right now, as they are structurally as strong as metallic alloys, but weigh a lot less. This is why all modern planes contain much higher percentages of composites than older aircraft, as they need to be more fuel efficient and better performing.

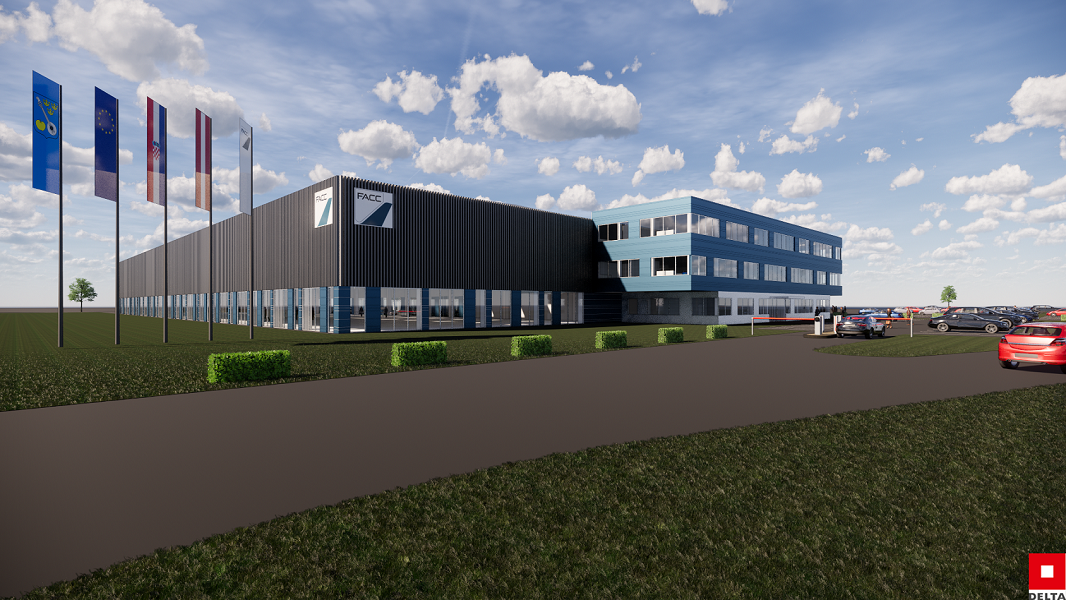

Naturally, this has lead to a growth in the demand for composites, and FACC is one of those manufacturers who is called to accommodate this rise quickly. In this context, the company has announced an investment of 30 million Euros to build a composite facility in Zagreb, Croatia. The new production unit will manufacture composite cabin components for commercial and business aircraft, covering an area of 12200 square meters, and employing more than 600 workers. The first products to come out of its production lines are expected to do so by March 2021, so this is going to be a rapid development.

According to the CEO of FACC AG, Mr. Robert Machlinger, the new Croatia-based aerospace facility will implement leading-edge technology, automation, and “Industry 4.0” methods. For those unfamiliar with the term, this means that there is going to be an extensive deployment of automated and intercommunicating cyber-physical systems, allowing for highly flexible, self-optimizing, self-configurable, and self-diagnosis enabled systems that are capable of supporting workers in highly complex work. This includes augmented reality systems for the workers, 3D printing, human-machine interfaces, IoT solutions, big data analytics deployment, cloud computing, and cognitive computing.